By Nicole Johnson

Only 2 percent of vehicles are electrified to date, but that is projected to reach 30 percent by 2030. A key toward improving the commercialization of electric vehicles (EVs) is to heighten their gravimetric energy density — measured in Watt hours per kilogram — using safer, easily recyclable materials that are abundant. Lithium-metal in anodes are considered the “holy grail” for improving energy density in EV batteries compared to incumbent options like graphite at 240 Wh/kg in the race to reach more competitive energy density at 500 Wh/kg.

Yan Yao, Ph.D., professor of Electrical and Computer Engineering at the Cullen College of Engineering at the University of Houston, and UH postdoc Jibo Zhang are taking on this challenge with Rice University colleagues. In a paper published June 17 in Joule, Zhang, Yao and team demonstrate a two-fold improvement in energy density for organic-based, solid state lithium batteries by using a solvent-assisted process to alter the electrode microstructure. Zhaoyang Chen, Fang Hao, Yanliang Liang of UH, Qing Ai, Tanguy Terlier, Hua Guo and Jun Lou of Rice University co-authored the paper.

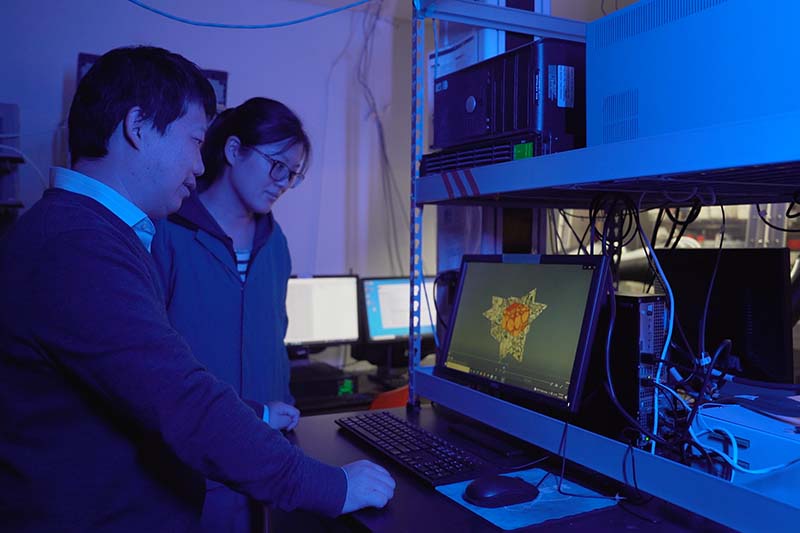

Yan Yao watches as student Benjamin J. Emley works in a glovebox. |

“We are developing low-cost, earth-abundant, cobalt-free organic-based cathode materials for a solid-state battery that will no longer require scarce transition metals found in mines,” said Yao. “This research is a step forward in increasing EV battery energy density using this more sustainable alternative.” Yao is also Principal Investigator with the Texas Center for Superconductivity at UH (TcSUH).

Any battery includes an anode, also known as negative electrode, and a cathode, also known as positive electrode, that are separated in a battery by a porous membrane. Lithium ions flow through an ionic conductor — an electrolyte, which allows for the charging and discharging of electrons that generates electricity for, say, a vehicle.

Electrolytes are usually liquid, but that is not necessary — they can also be solid, a relatively new concept. This novelty, combined with a lithium-metal anode, can prevent short-circuiting, improve energy density and enable faster charging.

Cathodes typically determine the capacity and voltage of a battery and are subsequently the most expensive part of batteries due to usage of scarce materials like cobalt — set to reach a 65,000-ton deficit in 2030. Cobalt-based cathodes are almost exclusively used in solid-state batteries due to their excellent performance; only recently have organic compound-based lithium batteries (OBEM-Li) emerged as a more abundant, cleaner alternative that is more easily recycled.

“There is major concern surrounding the supply chain of lithium-ion batteries in the United States,” said Yao. “In this work, we show the possibility of building high energy-density lithium batteries by replacing transition metal-based cathodes with organic materials obtained from either an oil refinery or biorefinery, both of which the U.S. has the largest capacity in the world.”

Laser cutting a solid state battery casing. |

Visualizing battery internals under stress. |

Cobalt-based cathodes generate 800 Wh/kg of material-level specific energy, or voltage multiplied by capacity, as do OBEM-Li batteries, which was first demonstrated by the team in their earlier publication, but previous OBEM-Li batteries were limited to a low mass fraction of active materials due to non-ideal cathode microstructure. This capped total energy density.

Yao and Zhang uncovered how to improve electrode-level energy density in OBEM-Li batteries by optimizing the microstructure for improved ion transport within the cathode. To do this the microstructure was altered using a familiar solvent — ethanol. The organic cathode used was pyrene-4,5,9,10-tetraone, or PTO.

“Cobalt-based cathodes are often favored because the microstructure is naturally ideal but forming the ideal microstructure in an organic-based solid-state battery is more challenging,” Zhang said.

On an electrode level, the solvent-assisted microstructure increased energy density to 300 Wh/kg compared to the dry-mixed microstructure at just under 180 Wh/kg by improving the utilization rate of active material significantly. Previously, the amount of active materials could be increased but the utilization percentage was still low, near 50 percent. With Zhang’s contribution, that utilization rate improved to 98 percent and resulted in higher energy density.

“Initially I was examining the chemical properties of PTO, which I knew would oxidize the sulfide electrolyte,” Zhang said. “This led to a discussion on how we might be able to take advantage of this reaction. Together with colleagues at Rice university, we investigated the chemical composition, spatial distribution and electrochemical reversibility of the cathode-solid electrolyte interphase, which can provide us hints as to why the battery could cycle so well without capacity decay,” Zhang said.

Over the last 10 years, the cost of EV batteries declined to nearly 10 percent of their original cost, making them commercially viable. So, a lot can happen in a decade. This research is a pivotable step in the process toward more sustainable EVs and a springboard for the next decade of research. At this rate, perhaps just as literally as euphemistically, the future looks much greener on the other side.

This research was funded by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE), as part of the Battery 500 Consortium.

Read Research Paper Online: Microstructure engineering of solid-state composite cathode via solvent-assisted processing (Joule)