Cullen College of Engineering Ph.D. student Zhaoyang Chen’s research article, “Manipulating Hardness to Construct Favorable Electrode Microstructures for All-Solid-State Batteries,” was not only published in the highly-respected, peer-reviewed journal Advanced Energy Materials this November, but it also earned a spot on the issue’s cover.

This research builds on work initiated in 2021 in the lab of Yan Yao, Hugh Roy and Lillie Cranz Cullen Distinguished Professor in the Department of Electrical and Computer Engineering.

With their first related paper, published in 2019, Yao’s group reported on the use of organic materials in solid-state sodium batteries. Then, in 2021, they published another paper — second-authored by Chen — investigating the composite cathode, which combined the use of safer, more efficient solid electrolytes and organic electrode materials.

“We started this work back in 2021,” Chen said. “In our first paper, we focused on the microstructure in the organic composite electrode, and observed we could reverse the microstructure, but we didn’t fully understand why. In this work, we figured out that the main reason is due to the mismatched mechanical properties of the two components — the organic compound and the solid electrolyte — and we identified a better way to control microstructure.”

Their newest article demonstrates an innovative methodology, according to Chen and Yao, to address the issue of microstructure optimization in all-solid-state batteries.

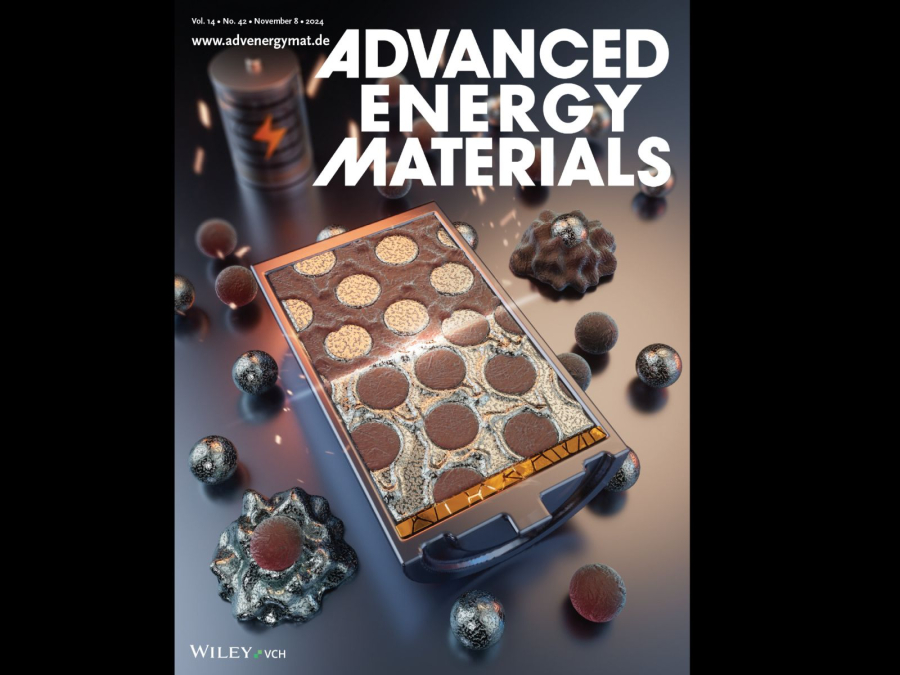

“With our cover,” Chen added, “we want to show the differences in microstructure. The key concept is reducing the hardness of the solid electrolyte to make it softer than the organic compounds. This inversion of mechanical properties reverses the unfavorable microstructure, improving electrochemical performance.”

The cover art features a shiny, silver-colored metal of the harder solid electrolyte alongside a wavy, brown “chocolate” texture for the softer organic materials. The boundary line between them represents how Chen’s method reverses the microstructure into a more favorable arrangement.

Inorganic materials, which are mechanically harder than solid electrolyte, facilitate the desired ionic percolation but rely on costly and supply chain limited metals used for cathode. In contrast, organic materials composed of abundant elements such as carbon, nitrogen and oxygen are mechanically softer but struggle to achieve sufficient ionic percolation when compacted with solid electrolytes.

Chen and Yao developed a novel solvent treatment method to address this issue. By treating solid sulfide electrolytes and combining them with PTO (an organic compound), the method inverts the hardness relationship. This results in a favorable microstructure that mimics the ionic percolation efficiency of inorganic materials while maintaining the benefits of organic compounds. This process represents the culmination of years of research work by Chen, Yao, and their colleagues, including ECE research assistant professor and LiBeyond CTO Yanliang Liang, Ph.D.

“These changes result in the formation of favorable microstructure, improving material utilization and performance,” Yao said. “We also show that this hardness manipulation strategy is not limited to this specific organic material; it can also be applied to other soft cathode material, like sulfur, for solid-state batteries. This work opens a new direction for understanding and controlling battery microstructure.”

The new method sets the stage for a variety of successes for advancing the energy density and safety of batteries. Benefits of all-solid-state batteries include reduced fire risk and increased safety compared to liquid-state batteries, reduced dependence on rare earth materials, greener and cost-saving opportunities by centering abundant organic materials in production, and increased performance in terms of charge time, charge capacity, and general usage improvements.

“Our group pioneered the conformal organic cathode for solid-state batteries, and we’re excited to collaborate with other leading experts in the Energy Storage Research Alliance,” Yao added. “Over the next five years, we aim to uncover new redox-active organic materials and reaction mechanisms.”

Chen echoed this enthusiasm, sharing her plan to remain in Yao’s research group as a postdoctoral researcher to continue advancing this innovative work.