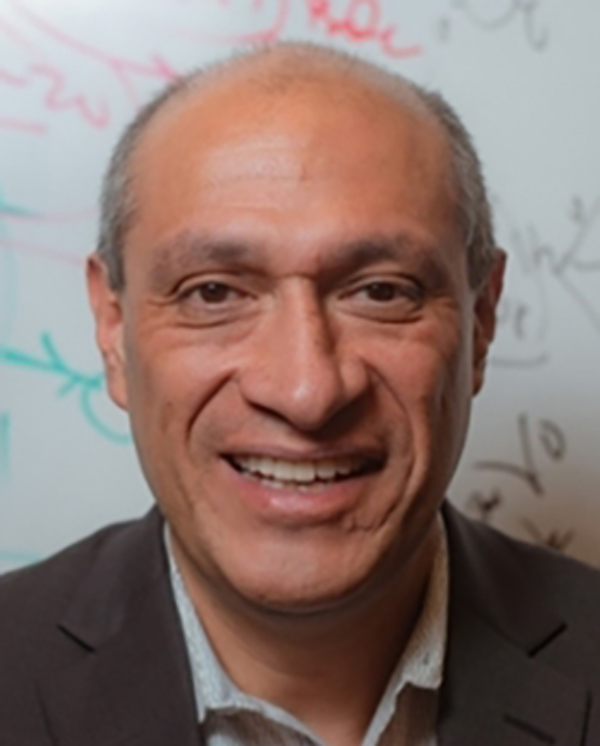

Professor of mechanical engineering technology Francisco C Robles Hernández, Ph.D., has been awarded $187,914 by the US Department of Transportation (USDOT) Federal Railroad Administration (FRA) to investigate a novel method of neutral temperature determination on the nation's railroads. This project is his latest in a long line of endeavors spanning 20 years of railway collaboration.

"This is part of a much larger project that I have with the Federal Railroad Administration. In this particular project, we're trying to obtain proof of concept in measuring the residual stresses that are built up [in railroad tracks] as temperature changes. It has to do with temperature, but not exactly the way we typically understand temperature," he explained.

When rails are installed in-track, the residual stresses are minimum. The environmental temperature at which this welding occurred is known as the neutral, or zero-stress, temperature, but thermal expansion and contraction effects can cause compressive and tensile stresses to build.

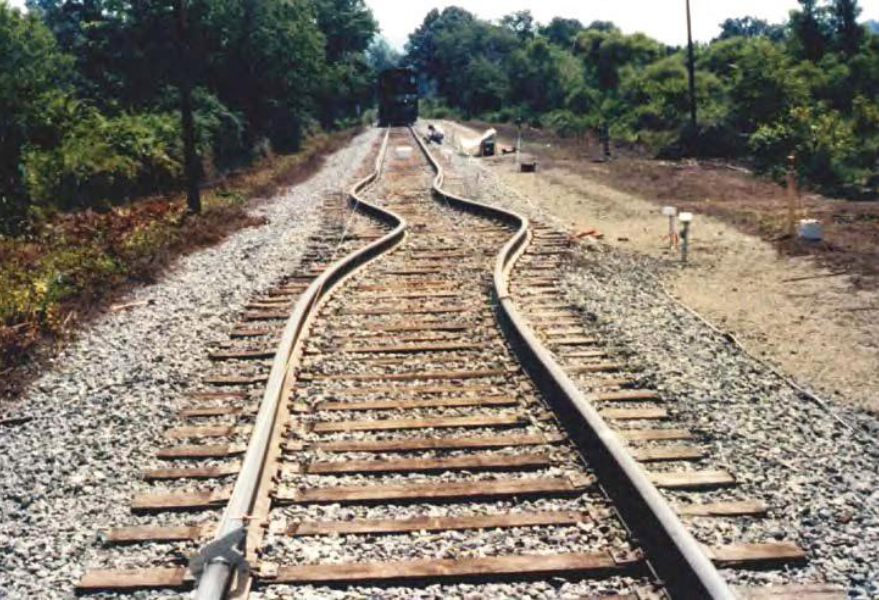

This expansion and contraction – and therefore buckling or breaking – of rails due to fluctuations in temperature is a problem that has plagued global railways since their inception over two centuries ago, and in those 200 years, humanity has yet to divine a solution.

When railroads experience significant enough stresses, they can become detached from their fastening systems. This can result in lateral deformations such as buckling – large S-shaped curves or kinks in what should be otherwise neatly-aligned rails. These changes increase the risk of derailment events, which can have serious impacts on safety and productivity, and incur costs and damages in the tens of millions of dollars per derailment as a result.

The USDOT Volpe Center, which was established to "bring technical capability and a future-oriented outlook to pressing national transportation issues" is dedicated to addressing a wide array of transportation-related issues in the US. One focus of the center is to better understand and monitor the factors related to this buildup of residual stresses, with the goal of being able to predict when a track may be in imminent danger of buckling.

"What we are proposing is to use ruby and sapphire to help measure the stress built up due to expansion and contraction," Robles Hernández said. "We can measure the light emissions of these rubies and sapphires, and based on the shift in their Raman emission, we are able to determine the stresses that are directly associated with temperature changes."

This non-destructive monitoring method won't require any installation steps that may further compromise the integrity of the rails; rather, the deposition of ruby and sapphire is non-invasive and requires no further modifications to the track.

"I've been working for the railways for almost 20 years, and this is a problem we still haven’t been able to solve," said Robles Hernández. "I think I have the ability to gain a better understanding of the problem, and that's why I decided to go in this direction."

"We have succeeded with similar methods for electronics. Now, we will prove the technology for the railways," he added. "Here, we are demonstrating and proving the technology for in-track use. Overall, we intend to ensure a fast, safe, efficient, and convenient railway system for trackside stress measurements, to meet our national interests and enhance the American quality of life by understanding rail track changes due to the effects of temperature."