Two papers recently co-authored by Kamel Salama Endowed Assistant Professor of Mechanical & Aerospace Engineering Tian “Tim” Chen, Ph.D., represent a new technological and engineering-focused foray into one of humanity’s oldest fields: fiber works. Specifically, knitting.

“Knitting is actually really intriguing because it arranges yarns or threads into interconnected loops, which combine to make much of the clothing that we wear every day without any adhesives or glue; the only thing that’s holding these fibers together is their mechanical interactions,” said Chen. “We want to understand why, so in my lab, we focus on geometry and mechanics. We want to understand how the intricate geometries of different materials give rise to their mechanical behavior.”

“[Knitting] is not traditionally seen as engineering research, but in the past decades, the definition of mechanical engineering has broadened greatly,” he continued. “It’s because of the great engineers of the past who solved really hard problems that we started to venturing into this whole new dimension of research that focuses on soft and flexible systems with much more complicated geometries.”

The word textile derives from the Latin verb texere, meaning “to weave”; texere, in turn, shares the same Indo-European root teks, also “to weave”, with the Latin techne, meaning “skill” or “craft.” While weaving and knitting are two distinct methods of creation, this etymological genealogy highlights the deeply interconnected relationship between textiles and technology – the skilled and practical application of knowledge.

“We wanted to investigate these mechanical systems that are very intimately connected to human systems,” he explained. “We already have a pretty good idea about how stiff things like steel and concrete work, but we don’t have a very good idea about how soft things work. Our theories were all developed for things like building a bridge or an airplane; we don’t have a lot of theoretical background for things that are very soft and interconnected.”

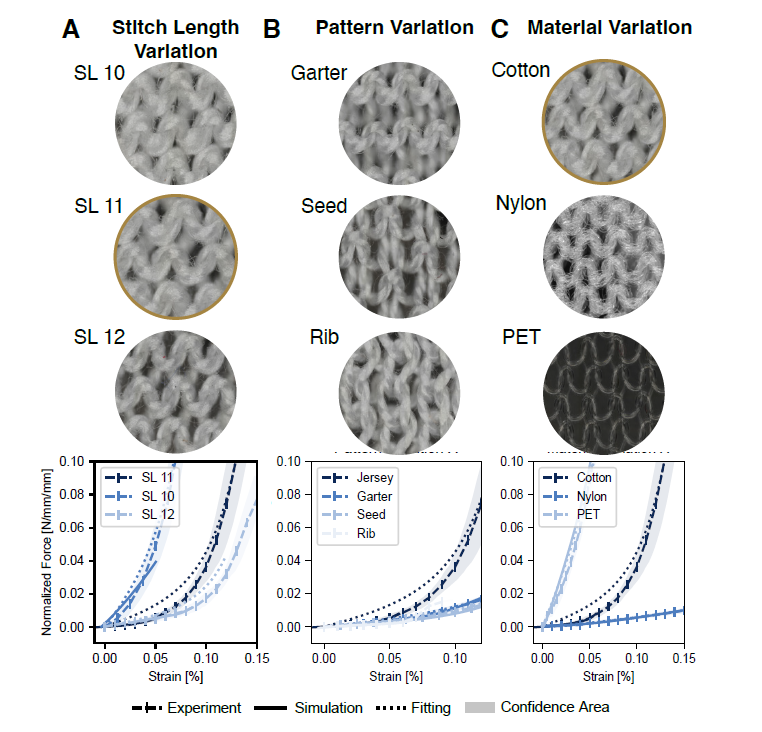

The first paper, “Haptiknit: Distributed stiffness knitting for wearable haptics,” sought to establish a quantitative understanding of what intuition was already telling Chen: this pattern is stiff, that pattern is soft, and if one were to insert and inflate a balloon between the two layers, the stiff layer would be expected to deform less than the soft part.

Their intuition was not far off. Subsequently, “Knit Happens: Designing the Mechanics of Machine Knitting,” set out to significantly simplify the system to allow the researchers to begin assigning quantitative values and working on algorithms to further similar project designs.

Chen’s interest in mechanical knitting machines and their potential capabilities came by chance after speaking to a colleague about their many current capabilities: differences in yarn and material, pattern, and tension all contribute to the generation of many unique items from the same machine.

“It’s almost like a 3D printer in that sense,” Chen said. “With a normal ink printer, we control the color of every dot, and we get a picture. Here, if you think of a loop in a knit as one pixel, we control the knit parameters at every pixel. This gives us a lot of design freedom, so we thought it would be an interesting system to study from a mechanical perspective.

“For example, what kind of knit gives you stiff behavior? What kind of knit gives you soft behavior? How do you solve for specific behaviors on certain parts of the body? How do you achieve this through designing the pattern of the knit?”

“We wear knits every day, and we’re still limited by the machines that make them,” he continued. “We made those machines because we have these manual patterns, so we designed the machines to replicate those patterns. We just never really thought about whether there are other patterns that do something functionally different that we still don’t know about.”

The machine used by Chen’s team is identical to those used in the fabric industry, meaning that their findings are “very translatable to mass production.”

Overall, though, they “want to understand the mechanical behavior of anything that has these flexible fibers going through them, whether it’s a knit or weave or even a crochet.”

“If that’s the case, then we said we could 3D print the same thing… and we kind of did,” Chen said, teasing the findings of an upcoming paper expected later this spring.