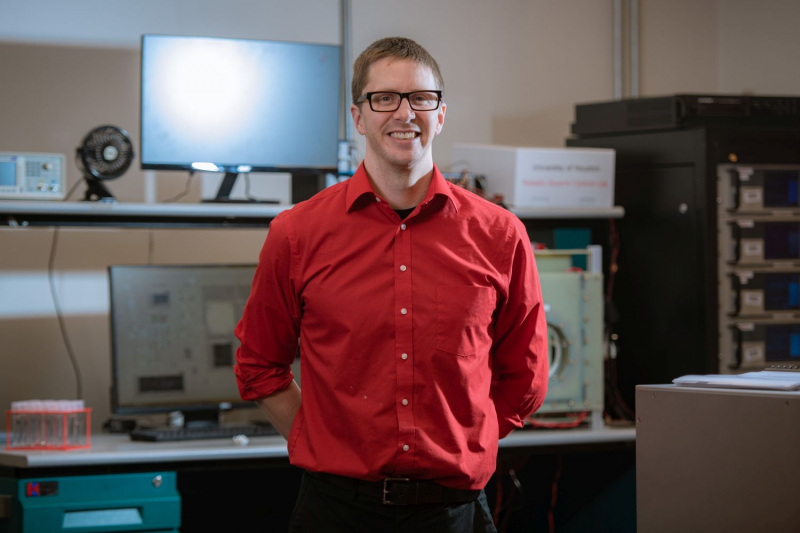

As he puts it, Aaron T. Becker, Ph.D., an Associate Professor in the Electrical and Computer Engineering Department at the Cullen College of Engineering, is interested in finding “a new type of small-scale manufacturing method, with the precision of modules, the reusability of Legos, and the self-assembly of DNA.”

Now, Becker has received a $299,963 grant from the National Science Foundation for his proposal, “Magnetically-Controlled Modules with Reconfigurable Self-Assembly and Disassembly.” It is research that has grown from his initial CAREER award, and from collaborations with colleagues in Dallas and Germany.

Becker said his research is ultimately about using self-assembly and magnets to improve things like health outcomes. He used an example of self-assembly in a surgery setting.

“Often, it is hard to get a robot inside places like a human body, because you have to cut a hole big enough for the robot to reach inside,” he said. “However, living things can be build inside human bodies because they use self-assembly – consider the wonder of a developing baby inside the womb, where the baby’s body is executing programs stored in her DNA. However, DNA is tiny, and making something in the centimeter scale takes months of constant effort.”

Becker's goal is to create small, magnetic building blocks, which can then be used to build structures and modules that can be assembled and disassembled.

“Like DNA, the magnetic patterns we encode on the sides of the modules control how they can connect and what shapes we can build,” he said. “We use magnets because we can push, twist and pull on them by using larger, computer-controlled magnets that are outside the body. This allows us to put the complicated, power-hungry parts – the magnets, magnetic controller and motion planner – outside the body and use relatively simple cubes with different patterns of permanent magnets inside the body.”

Becker often likes to compare the process to that of playing with LEGO blocks, because it's easy for someone to envision and to understand the appeal of. He compared his love of the building medium to that of his children's love of it now.

“As a kid, I loved Legos, and today my four boys love Legos,” he said. “However, my wife discovered something interesting – Our boys will happily play with a box of Legos for a couple of days, but once all the pieces are incorporated into fantastic creations... The boys lose interest and their creations gather dust. Then my wife and I need to sneak into the play room at night and disassemble the pieces. The next morning, after brief mourning, the boys return to building and creating. Learning how to make reusable robot modules is exciting in a similar way.”

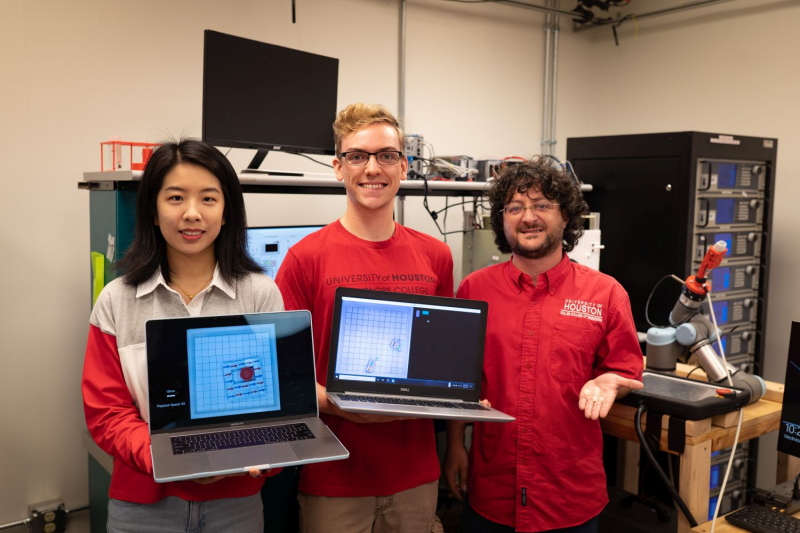

Becker identified two students that will be helping him with his research.

“Yitong Lu, a Ph.D. student, did incredible work on the motion planning and simulation that helped generate this grant,” he said. “She is researching better planners and techniques. Undergraduate researcher Conlan Taylor is developing image feedback so that we can improve the speed and quality of our assembly.”

The research is scheduled to start on Jan. 1, 2022, with an estimated length of two years.