A graduate student at the University of Houston is one of two lead co-authors for a paper by the Ryou group about combining the best qualities of semiconductors, to make them cheaper and higher quality.

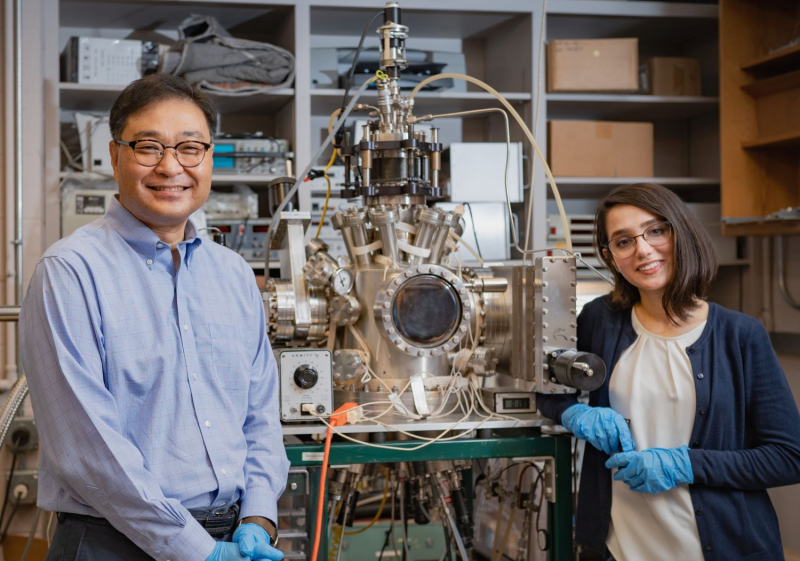

“Flexible single-crystalline GaN substrate by direct deposition of III-N thin films on polycrystalline metal tape” was published in Journal of Materials Chemistry C. Mina Moradnia, a doctoral student of Jae-Hyun Ryou, Ph.D., Associate Professor of Mechanical Engineering, served as one of the primary authors for the paper. Shahab Shervin, Ph.D., formerly a research assistant professor of Mechanical Engineering and now a senior materials scientist and engineer at ASML, served as the other primary author.

Additional contributors from UH included Jie Chen, Sara Pouladi, Kamrul Alam, Tain Tong, Jiming Bao, Rebecca Forrest and Ryou. Additional authors include Mi-Hee Ji, Russell D. Dupuis and Theeradetch Detchprohm of the Georgia Institute of Technology.

Moradnia described her work as attempting bridge the gap between high performance, “single-crystalline” semiconductors and low-cost, “non single-crystalline” semiconductors.

“My research is the first demonstration to bridge the gap by developing a new technology enabling the deposition of the single-crystalline semiconductor film, for high performance, directly on the non-single-crystalline substrate, for low-cost manufacturing,” she said. “Furthermore, it provides a material platform for flexible electronics because it uses flexible metal substrate.”

Going forward, Moradnia sees multiple areas of research and application for the new technology the lab is developing.

“Without question, the flexible platform will be the next generation of devices for the growing demand of the industry,” Moradnia said. “Consequently, new flexible devices with versatile applications and a continuous production line with reduced fabrication costs will be explored. Moreover, the integration of Silicon (Si) based industry with III-N industry will happen in near future based on our developed deposition technique. New applicable technology is the key to reduce costs, improve performance and increase the production of semiconductor-based devices.”

Moradnia identified four areas for development:

- Replacing the brittle semiconductor wafers with flexible templates for versatile (flexible and wearable) applications.

- Employing thin-film-based, high-quality semiconductor materials as a platform for high-performance device technology.

- Replacing expensive and limited-area single-crystal substrates with inexpensive polycrystalline substrates to address economic manufacturing issues.

- Employing flexible tape substrate for easily scalable process with continuous deposition via roll-to-roll growth.