Thanks to laboratory testing contributed by a team led by Dr. George K. Wong of Petroleum Engineering at the University of Houston's Cullen College of Engineering, a controlled mud level horizontal gravel pack – an industry first – was executed by Shell at the Perdido field in the Gulf of Mexico.

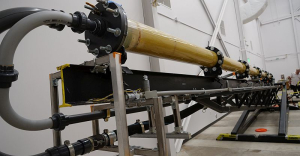

According to Wong, testing for verifying placement of light weight proppant and gravel pack modeling were done with the department's newest 30-foot flow loop. Test results were deployed successfully in Shell’s Perdido, the world’s deepest offshore drilling and production spar, in early September.

Wong said the effort took roughly six months for his team, which consisted of himself as PI, Petroleum Engineering Research Lab Supervisor Carlos Ortiz, and two consultants, Tony Bernardi and Mike Vann. Engineers from Shell were also involved with the design of the test program.

“The project timeline was critical as Shell needed test results to meet their field deployment schedule,” Wong said. “We delivered all test results safely and on schedule.”

C. C. Lin, a Well Delivery Production Technologist for Shell’s Perdido, concurred with Wong's assessment.

“The main challenge for this project was performing the open hole gravel packing completions within low pore-pressure and fracture gradient margin reservoirs,” Lin said. “Shell’s project team evaluated three separate labs and concluded that the lab at UH has the technical capabilities and equipment that best accommodates the needs of the program, and UH has the experienced technical team members that will definitely shorten the time needed for the overall success.”

Lin added, “Because of all of these advantages that UH offers, the Shell team initiated the reach-out to UH for this particular project.”

Wong identified five aspects to the work his team did:

- Developing the test program with Shell.

- Setting up the lab to meet Shell’s technical, and HSE (health, safety and environmental) requirements.

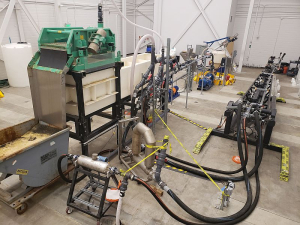

- Integrating all equipment and required data acquisition components of the flow loop system (pumps, blender, solids-mud shaker, flowmeter, pressure sensors and other equipment).

- Demonstrating the integrated system meets Shell’s specifications.

- Completing the test program of the project safely and on schedule.

“I’d like to highlight this is a new flow loop laboratory at UH, with Certification of Occupancy granted in November of 2019, and the first research project in this lab,” Wong said. “The success of this project is particularly impressive given the short time fuse and challenges of working in a new facility.”

Lin echoed Wong’s remarks, confirming that the collaboration with UH included the planning, setting, preparations and execution portion of the project.

“The UH project team responded well throughout the entire project with the Shell team,” he said. “A strong background knowledge of these testing objective and execution from the UH team helped the Shell Team accomplish the new material tests on time, on budget, and achieve a 'Goal Zero' on HSE performance.”

Dr. Mohamed Soliman, the William C. Miller endowed chair professor and the Department Chairman of Petroleum Engineering, praised the collaborative effort and Wong’s work.

“Dr. Wong is one of the top experts in this area.” Soliman said. “He has a long history of solving the most challenging technological problems and developing innovative techniques for completion.”

Wong said the project was an example of the power of synergy between industry and academia with the full support of UH. The flow loop equipment in the new lab was donated by Shell.

“In Petroleum Engineering, connection between industry-university is essential to stay abreast of the current and upcoming technical challenges facing in the industry,” he said. “In this case, we have demonstrated our new laboratory capability and our ability to collaborate with an industry partner on applied research projects that deliver immediate and added-value results.”

When asked if Shell would be open for future JIP, Lin responded, “UH and Shell have a very positive and longstanding relationship. After this successful and valuable collaboration, UH could very likely be on the candidate evaluation list when Shell prepares for another mutually beneficial project,” he said.