An article citing improvements in research involving a new generation of flexible photovoltaic devices reported by the Selva Research Group at the UH Cullen College of Engineering was recently published in the journal Energy & Environmental Science. The article is titled “Flexible GaAs Solar cells on roll-to-roll processed epitaxial Ge films on metal foils: a route towards low-cost and high-performance III-V photovoltaics.”

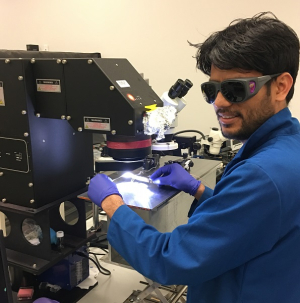

The research improvements are based on the collaborative effort undertaken with UH’s Ryou Research Group and funded by the U.S. Department of Energy’s SunShot Initiative, which seeks to make solar energy and electricity affordable for American consumers. The Selva group fabricated all materials used in the solar cell and made the devices, known as the “single junction gallium arsenide solar cells,” while the Ryou group helped in modeling of the devices and supported its fabrication.

The article reports a 50 percent higher efficiency in gallium arsenide solar cells – also known as GaAs – on inexpensive metal substrate than a previous article on the project published in the journal Progress in Photovoltaics: Research and Applications.

“We achieved higher efficiency through improved materials growth and device fabrication,” said Venkat Selvamanickam, M.D. Anderson Chair Professor of mechanical engineering, who leads the Selva Group. “The underlying template of germanium used in this new work was made by a different process – plasma enhanced chemical vapor deposition (PECVD) – that led to better gallium arsenide material quality and better solar cell performance.”

The goal of the project is to develop methods to fabricate gallium arsenide solar cells at a low cost.

“Low-cost flexible GaAs solar cells can help us meet our future energy demands,” said Devendra Khatiwada, a materials science and engineering doctoral student working with Selvamanickam. “In today’s market, the majority solar cell technique is still based on silicon, but researchers are facing limitations of silicon’s properties.”

While the highest efficiency solar cells are made with gallium arsenide, they are very expensive and are primarily used in space and military applications. The biggest component of the cost is the wafer on which these solar cells are made. Khatiwada shared that an eight-inch diameter wafer of GaAs could cost around $5,000 in comparison to $5 for a similarly-sized silicon base.

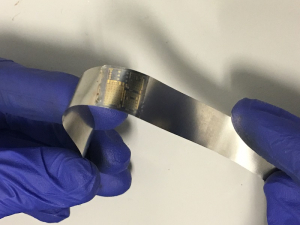

“We are replacing the wafer with an inexpensive metal foil. The metal foil allows roll-to-roll continuous manufacturing which can further lower cost,” Selvamanickam said. “We have developed methods to grow single-crystalline-like templates of germanium (a commonly used substrate for gallium arsenide) on flexible, inexpensive metal foils. The templates were then used to fabricate the gallium arsenide solar cells.”

In this new publication, the team made high-quality germanium films by roll-to-roll PECVD and then used them to fabricate gallium arsenide solar cells of improved quality and 50 percent higher efficiency.

“We believe our technology will address costs related to GaAs photovoltaics and all associated applications,” Khatiwada said. “Manufacturing these cheaper and flexible GaAs solar cells will diversify their use – from space photovoltaics to terrestrial.”

While celebrating project gains, the UH researchers are not ready to rest on their laurels.

“We are working to further improve the materials quality, device fabrication and the efficiency of the gallium arsenide solar cells,” Selvamanickam said.

Energy & Environmental Science links all aspects of the chemical, physical and biotechnological sciences relating to energy conversion and storage, alternative fuel technologies and environmental science.

To read the article, please visit: https://pubs.rsc.org/en/Content/ArticleLanding/2019/EE/C8EE02553C#!divAbstract