Konstantinos Kostarelos, associate professor in petroleum engineering, is building a new device to address the issue of blockage inside crude oil pipes. It’s a big problem in the oil industry. Companies typically spend a lot of money on chemical dispersants and inhibitors to address the issue and then they may still have to physically clean out the pipes by scraping the solids that have accumulated with devices called “pigs.”

Kostarelos has a new approach that might eliminate all of that.

His prototype uses an electric field to attract the components in crude oil that cause the blockage and remove them from the flow stream. His method has been published in the Journal of Petroleum Technology.

How the slowdown happens

It is not too refined a world in the business of crude oil. The black gold flows through pipes on its downstream journey to get it ready for consumers. But over time, imagine what the inside of that pipe might look like, filled with sludge buildup that prevents the pipe from filling to capacity and the Texas Tea from smoothly moving on.

Molecules called asphaltenes make up the heaviest fraction of crude oil, and they are known to precipitate with pressure and temperature change outside the reservoir. Over time that precipitation builds up and hardens on the inside of the pipe.

“You have a clean pipe and things flow normally, but the coating of the asphaltenes inside the pipe builds up, so if your pipe diameter was six inches, it slowly becomes five inches, then four inches, so the pipe size is not what was designed,” said Kostarelos.

When that happens the flow rate of the oil is reduced and if pumps are used to increase the flow rate, there will be an enormous amount of pressure needed from the pump.

A better way

Kostarelos is accustomed to finding better solutions. Last year he designed a way to use applied enhanced oil recovery methods to clean up the site of an underground fuel leak in Denmark, recovering 35,000 kg of jet fuel.

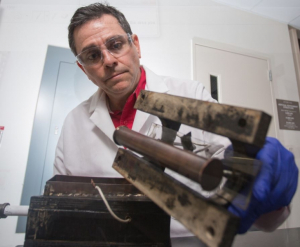

This time he built a prototype device that would electro-kinetically remove asphaltenes from crude oil near the point of production. He was helped along by his undergraduate students Clint Martin, Kyo Tran, Jose Moreno and Aaron Hubik.

The process involves putting two electrical plates, highly charged at 4,000 volts, into the pipe. They attract the molecules to them and away from the pipe.

“The asphaltene molecules, which are polar, start coating the plates and we remove the plates,” said Kostarelos. “It worked better than I expected,” he adds with a smile.

The idea just came to Kostarelos. Like oil, it just flowed. “I thought this would be an interesting method we might be able to use to address the flow assurance problem instead of using the chemicals or pigging the pipe, but no one had done it before.”

So he did.

“It’s still in the early stage and we have to explore how to optimize the device to make it as efficient as possible in removing particles,” he said.

So he will.