That exciting feeling you get when you've made a breakthrough discovery and you know that something that seemed impossible yesterday is now completely clear – that's the feeling that Stanko Brankovic, professor of electrical and computer engineering, has about his recent discovery of the speed in which catalysts are formed.

“I’m in the same position as Sir Isaac Newton was when the apple hit him in the head! It’s that same excitement, a ‘Wow!' moment,” said Brankovic.

Newton’s not-too shabby discovery resulted in nothing less than an understanding of gravity; Brankovic’s may result in building better catalysts, the fundamental substance that speeds up reactions in all industries from petrochemical to manufacturing.

Brankovic is not alone in his excitement. The Journal of the Electrochemical Society selected Brankovic’s paper as the “editor’s choice” article, a distinction reserved for research highlighting transformative scientific discoveries. According to the journal, the designation is awarded for work showing extraordinary direction, concept, interpretation or way of doing something. The journal is the most acclaimed publication in its field.

Brankovic’s article is titled “Reaction Kinetics of Metal Deposition via Surface Limited Redox Replacement of Underpotentially Deposited Monolayers Studied by Surface Reflectivity and Open Circuit Measurements.”

Building a better catalyst

Brankovic and his group studied what affects the speed in which catalysts are formed by examining how quickly the thin-film monolayers are placed on top of each other to build them. Their results showed clearly that reaction kinetics of metal deposition is significantly impacted by the design of the reaction solution and ion concentrations.

Nobody understood this before Brankovic.

“The speed in how quickly you put these monolayers down effects their morphology, and that effects the monolayer quality in terms of their catalysis performance,” said Brankovic, noting that a catalyst will become something different depending on the speed with which the layers are stacked.

Knowing that catalysts become different dependent on the speed of their architecture gives scientists more control over what they are creating.

“We discovered some fundamentally important things that will eventually help people who use this method to design even better catalysts and control the design process better,” said Brankovic.

Body of work

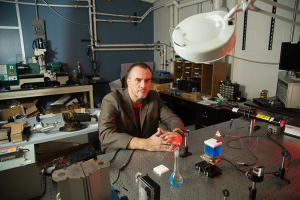

Although Brankovic has toiled away at thin film deposits for more than a decade, they still absorb much of his brilliant mind.

“Everywhere you look is a thin film,” he said, pointing to his surroundings. “Paint is a thin film, windows are coated with thin films; in technology they exist everywhere. The world is made of thin films.”

His enthusiasm over thin-film layered catalysts has translated to hard work and lots of success in his field. In 2001, he was highly cited for his work on creating a catalyst for fuel cells, the kind that ultimately brought us the electric car. Recently the National Science Foundation awarded him a grant to make “heavy water” less expensively, which could lead to safer nuclear energy (spoiler alert: his method involves catalysts).

Despite his stature in the field, Brankovic credits his students with the latest accomplishment. “Together we have opened this door for others to follow,” he said.

His group includes his Ph.D. students Wu Dongjun, Ela Bulut, who has graduated and is now a professor in Turkey, Nikhil Dole, now graduated and employed by Lam Research, and the visiting scholar Dr. Hasan Kilic.

Brankovic is ultimately concerned about his students’ success. “This is the type of recognition that increases the visibility not only of UH, but of my students in their pursuit of excellence in academics and research.”

A catalyst for success you might say.