With help from a UH petroleum engineering professor, a technology originally developed by the oil and gas industry to extract residual oil from reservoirs is now being applied to clean up the site of an underground fuel leak in Denmark.

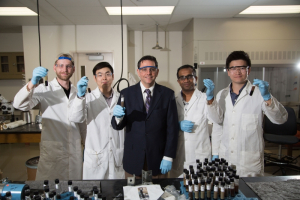

The novel application of the oil recovery technology was designed by Konstantinos Kostarelos, associate professor of petroleum engineering at the UH Cullen College, along with his graduate students and a cadre of talented collaborators from all over the world.

Kostarelos began working on this project in 2013 while serving as a faculty member at the University of Cyprus, after the Danish Ministry of Defense identified an underground pipeline at a fuel storage facility that leaked massive amounts of jet fuel into the ground. Over time, the leak spread to a groundwater aquifer, creating environmental concerns for nearby residents.

The Danish Ministry of Defense hired a private environmental consulting firm, NIRAS A/S, to carry out the implementation of the technology at the site of the fuel leak. NIRAS A/S then provided funding to Kostarelos and his students at the University of Cyprus to conduct preliminary laboratory research to support these efforts.

Crude oil development relies on both primary and enhanced recovery methods to extract all of the available oil from a reservoir. Primary methods, such as using pumps and the natural pressure inside of the reservoir to drive the oil to the surface, only recover about half of the total oil inside of a reservoir. Enhanced Oil Recovery (EOR) methods must be employed to recover the remaining oil, which is usually trapped inside of tightly packed sand or the microscopic cracks and pores in rocks.

One safe and efficient method of recovering residual oil involves injecting environmentally-friendly and biodegradable chemical formulations – usually made up of polymers and detergent-like surfactants – to allow the oil to flow more easily through the porous rocks. High-pressure brine is then injected into the reservoir, allowing the oil to flow downstream where it is collected at another well.

“As far as I know, we are the only group in the world applying this enhanced oil recovery method to cleanup the site of an underground fuel leak,” Kostarelos said.

After Kostarelos’ team identified the best formulations, the data collected from these tests was delivered to their collaborator Phillip de Blanc, an adjunct professor at Rice University and environmental engineer with the consulting firm GSI Environmental. Dr. de Blanc then runs numerical simulations on the data to predict how the surfactant formulation will perform on a much larger scale at the site of the fuel leak.

Since arriving at the University of Houston in 2014, Kostarelos and his graduate students have been conducting small-scale tests on rock core samples by replicating in-situ conditions and studying the effects that different surfactant formulations have on extracting the residual oil out of the rock pores.

Now that Kostarelos’ team has successfully designed this Enhanced Oil Recovery method for an entirely new application, clean-up efforts at the site of the fuel leak are fully underway. NIRAS A/S has divided the site into six stages, with two stages already completed. After completing each stage, or row, of the cleanup effort, NIRAS A/S reports the results to Kostarelos and his team, who then compare the data with the computer simulations and make adjustments to the formulations as needed.

So far, the success of the Enhanced Oil Recovery technology at removing the residual fuel at the site of the leak has surprised even Kostarelos.

“We recovered more fuel than anticipated, and the water that came up was more fuel-laden than any of us were expecting,” he said.

In total, 320 gallons of jet fuel were recovered from the first two rows of the site. In fact, so much fuel was recovered in these initial stages that the firm had to order storage tanks to temporarily hold the fuel-laden water until it could be treated.

Equally impressive as the technology’s efficiency at cleaning up the fuel, Kostarelos said, was the speed at which it works: the residual oil from each row was removed within one week.

The environmental consultants estimate that between 6,500 and 10,500 gallons of jet fuel remain in the contaminated aquifer at residual saturation. After the clean-up efforts come to an end, Kostarelos and his team plan to publish an article on the lessons learned from the project. So far, his group has presented their research at two conferences and will soon publish a paper in the journal Science of the Total Environment.

In addition to the speed and efficiency of this approach to cleaning up oil leaks or spills, Kostarelos said the use of surfactants allows for fine-tuning of the chemical formulations used in the cleanup efforts. A one-size-fits-all approach to cleaning up leaks and spills isn’t feasible because of the unique conditions of each site – that is, the temperatures, pressures, and other factors that can impact the success of oil recovery methods.

“This technology can be applied with tailoring to other sites throughout the world and yield as good of results as we’re seeing here, at other sites,” Kostarelos said.

Kostarelos said his team is also focused on improving the economy-of-scale for their surfactant formulations so that less of the formula needs to be used in order to get the same, or better, results.

To conduct this work, Kostarelos and his students are creating synthetic rock core samples to study the flow behavior of oil and their surfactant formulations. Typically, researchers looking to study the flow of oil through rock cores must order rock samples from the sites they wish to study, which can cost millions of dollars and take months or even years to receive a specimen that is only a few inches tall.

Kostarelos’ team, which includes three graduate students and research scientist Dr. Sujeewa Palayangoda, is currently perfecting a technique for synthesizing 12-inch-long homogeneous rock core specimens each week, allowing his group to conduct repeated tests without the exorbitant cost and time associated with getting rock core samples from the field.

All of this work, Kostarelos said, is extremely important for his graduate students – Travis Comer, Jay Ho Lee, Alex Lee – as they embark on their careers in petroleum engineering.

“Real world application is what I always strive for in my projects,” Kostarelos said. “It gives students the motivation to see something through to the end, because the research is tied to a real-world problem that needs to be solved.”