Two professors in the Cullen College of Engineering at the University of Houston earned Faculty Early Career Development (CAREER) Program awards from the National Science Foundation (NSF) this year. Each received a five-year, $500,000 grant for integration of outstanding research and educational outreach.

Bora Gencturk, professor of civil and environmental engineering, received his award for the use of novel materials to increase resiliency and sustainability of reinforced concrete bridge columns subjected to seismic hazards and deteriorated by environmental aging. Lars Grabow, professor of chemical and biomolecular engineering, received his grant to explore a novel chemical looping process for methane coupling to transform natural gas into more valuable commodity chemicals such as ethylene. Both researchers were also rewarded for their plans to create communities of learning including high school teachers and students, among others, in their research projects.

The foundation awards 600 grants each year to support development of academic careers that are dedicated to stimulation of the discovery process through inspired teaching and enthusiastic learning, according to the NSF website.

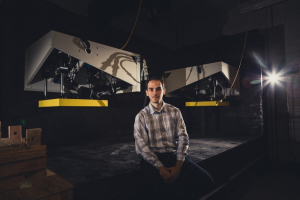

Bora Gencturk: Bridge design and construction to combat aging and earthquakes

Nationwide, the average age of bridges, which are generally designed for 50-year lifespans, is 42, according to data provided by the American Society of Civil Engineers. On a scale from A to F, the average grade for more than 600,000 bridges in the United States was a C-plus in 2013, and one-quarter of them were rated structurally deficient or functionally obsolete. The Federal Highway Administration estimates the cost to eliminate the backlog of bridge deficiencies at $20.5 billion annually until 2028. Currently, only $12.8 billion is spent each year.

Gencturk is working to improve durability and to lengthen lifespans of new and existing bridges. His research focuses on the combined effects of environmental aging and earthquakes on bridge infrastructure in the United States as well as the effects of using new materials for bridge construction. In the lab, Gencturk and his collaborators plan to produce representative columns with corrosion-induced damage to simulate environmental aging. Their objective is to study the load-carrying capacity of the bridges in aged conditions during regular operation and simulated seismic activity.

“The novel aspects of this study are the consideration of multiple hazards and the use of new, advanced materials to address those hazards,” Gencturk said.

Deterioration is caused primarily by rusting of steel reinforcement bars inside concrete bridge columns and by reduced capacity and resistance of bridges located in seismic regions. Concrete’s main flaw is that it cracks over time, and the cracks allow external environmental agents to penetrate the structures and rust the steel reinforcement. Earthquakes, which cause large horizontal drifts, can cause significant damage to bridge columns and can render entire structures dysfunctional in their aftermath.

“We want to understand how reinforced concrete behaves and propose a new design approach to improve durability and seismic performance of the bridges,” Gencturk said.

Gencturk and his team are studying conventional reinforced concrete structures to enlighten their understanding of applications for prefabricated ductile fiber-reinforced cementitious composite, DFRCC, counterparts. DFRCC provides increased crack resistance, higher tensile ductility and lower permeability. Another of Gencturk’s goals is to examine designs of existing bridge columns for comparison to new design and construction approaches.

“We’re not abandoning concrete and coming up with something totally new,” Gencturk said. “We want to use advanced materials in an optimal sense in bridges in order to reduce repair and maintenance costs, and to extend their lifetimes.”

Significant reductions in maintenance costs are expected because the materials are more resistant to environmental attacks and earthquakes. However, initial construction costs are expected to increase because DFRCC is more expensive than conventional reinforced concrete.

“Fortunately, the new bridges are expected to last at least twice as long – 100 years – which offsets initial increases in the long-term,” Gencturk said.

Gencturk hopes to see his research implemented in bridge construction in the next decade. He also envisions application of the innovative design technology to marine architecture including offshore structures, piles and ports as well as parking garages and other construction exposed to environmental conditions.

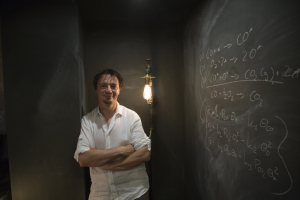

Lars Grabow: A novel application of hydrogen storage materials for the production of commodity chemicals by methane coupling

Methane, which is the abundant and inexpensive majority component of natural gas, would make an ideal feedstock for the fabrication of more valuable chemicals. However, engineers have not found a way to break the chemical compound’s strong carbon-hydrogen bond without burning the methane. Despite decades of research, they have not realized the potential for one of the most stable molecules known in chemistry.

“Methane is essentially spherical, like a ball with no point of attack, so it requires a lot of energy to break that C-H bond,” said Lars Grabow, assistant professor of chemical and biomolecular engineering at the UH Cullen College of Engineering. “It’s a very happy molecule.”

Grabow earned a prestigious National Science Foundation (NSF) CAREER Award to explore a novel chemical looping process for methane coupling to transform natural gas into more valuable commodity chemicals such as ethylene. The award totals $500,000 distributed over five years.

The foundation awards 600 grants each year to support the development of academic careers that are dedicated to the stimulation of the discovery process through inspired teaching and enthusiastic learning, according to the NSF website.

Exothermic reactions between methane’s hydrogen atoms and oxygen deliver the energy necessary to break the carbon–hydrogen bond at high temperatures, but they also form carbon dioxide, and the methane burns in the process.

“You can burn it, and that’s all the technology currently allows us to do with natural gas,” Grabow said. “That’s great if you want to use methane to generate heat to drive turbines and make electricity in a natural gas-fired power plant, but that’s not our objective.”

Grabow’s goal is to abstract hydrogen from methane to form new carbon-carbon bonds rather than to burn it. Engineers could use the resulting hydrocarbons, which would contain commodity chemicals like ethylene and ethane, to manufacture plastics, lubricants, cosmetics and pharmaceuticals.

“It can have a huge impact on the petrochemical industry,” Grabow said. “We could also make propane or polypropylene, and those are other big commodity chemicals primarily derived from petroleum right now.”

Grabow plans to isolate hydrogen with carbon in one reactor and hydrogen with oxygen in another, which physically separates the carbon from the oxygen to prevent them from forming the bond that produces carbon dioxide. The key to his strategy is a hydrogen storage material, which engineers have used in numerous applications including hydrogen-powered fuel cells for electric vehicles. Such reversible hydrogen storage requires weak hydrogen binding to allow release of the gas at later times, but many discovered compounds bind hydrogen too strongly.

Grabow’s idea for hydrogen abstraction from methane requires strong hydrogen binding, which could revive prior failed material discoveries. As the C-H bonds break in the first reactor, the hydrogen storage material absorbs the hydrogen like a sponge. The saturated material is moved to the regeneration reactor where the hydrogen is removed, and the material is ready to repeat the process.

“The preliminary data we gathered from literature as well as the hydrogen storage material database provided by the Department of Energy points to the fact that this concept can be realized,” Grabow said. “We just need to make sure that we design the right sponge, and we have several ideas about how to do this.”

Bill Epling, UH associate professor of chemical and biomolecular engineering, is lending his laboratory and experimental expertise to the project. Together, he and Grabow are in the process of designing a laboratory-scale reactor setup and training a graduate student to help test their ideas.

The overall reaction, which is two methane molecules coupled with the help of oxygen to make ethane, is called oxidative coupling of methane. Kinetics, transport phenomena and thermodynamics make the process possible. Kinetics refers to the rate of the C-H bond activation. Mass transport is required for the diffusion of hydrogen atoms through the metal’s outer layer to the center where the hydride phase forms. And thermodynamics provides the driving force for metal hydride formation and methane coupling.

The project’s simple methane reaction performed on different materials is conducive to individual and group projects, so Grabow intends to introduce the research to students in his undergraduate and graduate classes as well as a high school summer student. Ideally, Grabow wants his students to publish a paper from the classroom setting.

“The cool thing is that kinetics, transport and thermodynamics are the core disciplines of chemical engineering, so this project combines the course material that we teach all of our UH students in a fairly simple system,” Grabow said. “It provides an interesting framework for class projects that are relevant to our local oil and gas industry, and it allows me to bring my research interests to the classroom to enrich the students’ overall learning experiences.”