Metal buildings comprise almost 50 percent of all non-residential, low-rise construction in the United States. The most common configuration is the gabled frame with sets of exterior columns supporting rafters that form house-shaped peaks, and base plates serve as the load-resisting mechanisms that withstand horizontal forces, such as high winds.

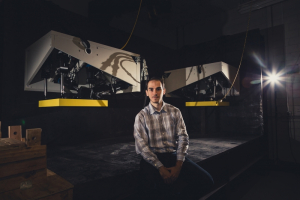

Bora Gencturk and Mina Dawood, assistant professors of civil and environmental engineering at UH Cullen College of Engineering, explored base plate connections in low-rise metal buildings in a preliminary study sponsored by NCI Building Systems. The results earned them a subsequent one-year $50,000 grant from the Metal Building Manufacturers Association, MBMA, with additional in-kind support to expand their research.

“The assumption was that the base acts like a hinge that freely rotates,” Dawood said. “For the purposes of design, engineers had neglected stiffness in connections because they could not really quantify it.”

Funded by MBMA, Gencturk and Dawood are conducting a systematic follow-up study in terms of isolating individual parameters of base plate connections to quantify their effects. The goal is to generate a realistic set of rules so that engineers can account for rotational stiffness of base connections in their designs.

“We are taking the first step in the process, which is research, so the association can take the information to code committees and develop design guidelines,” Dawood said.

The initial year-long study funded by NCI Building Systems quickly and economically tested and proved the premise that base connections provide some level of rigidity. In the lab, Gencturk and Dawood used steel columns and bases to avoid replacement of concrete foundations after each test. To simulate gravity loads, they applied thousands of pounds of force to the columns, cycling them back and forth horizontally, after which they measured displacements and rotations.

With numerical analysis techniques, they quantified the stiffness for a certain subset of gabled frames using the experimental data. They determined that they could curtail costs of manufacturing metal buildings by as much as 12 percent by reducing the amount of steel in other parts of the frames for which the rigidity of base plate connections compensated. For an average building, this translated to several tons of steel, which costs approximately 50 cents per pound.

“Understanding the metal building industry is important because just looking at the funding level of the study belies the impact of the research,” Dawood said. “Metal buildings are used in every sector of infrastructure including hospitals, churches, schools, shopping centers and industrial buildings.”

Low-rise metal buildings are typically selected on the basis of cost, so the industry is extremely cost competitive. Even minor savings can make a significant difference.

“You can think about how much enclosed space you see in warehouses and how little steel is used in their structures,” Gencturk said. “That gives you some sense of how much the manufacturers try to economize their construction by removing unnecessary weight.”