Most people just aren’t willing to pay $30 for a light bulb.

That’s the going rate for many LEDs, or light emitting diodes, which now sit on store shelves next to the compact fluorescent lights (CFLs) and traditional incandescent bulbs.

At their best, LEDs are three to four times more energy efficient than even the much-touted CFLs. Unfortunately, they only hit that peak only when operating at a very low current, which equals a low level of light. When producing an amount of light that people actually need, LEDs become far less efficient.

For example, to generate light equal to the output a 60-watt incandescent bulb, white LEDs consume nine to 10 watts of electrical power while CFLs use roughly 13 watts. This loss of energy efficiency, known as droop, drives up the cost of LED lighting, weakens its energy consumption advantage versus CFLs and hinders the technology’s commercial success.

Jay-Hyun Ryou, assistant professor of mechanical engineering at the University of Houston’s Cullen College of Engineering, is attempting to bring LEDs’ theoretical advantages to the real world. By extending their peak efficiency to a plateau, he’s aiming to create LEDs that produce as much light with as little energy as possible. The result should be cheaper devices that consume far less energy than competing products, making them winners for consumers and the environment alike. He has published papers on his efforts (in collaboration with Georgia Tech and Arizona State University) in Applied Physics Letters and IEEE Photonics Technology Letters.

The articles start with an interesting premise. Typically when researchers tackle a problem, they begin by looking for the root cause. While Ryou is interested in the cause of droop, which is still under serious debate, in practice it may not matter, he said.

“In general you try to identify the problem first and then come up with a solution, but the article says let’s tackle the problem first,” Ryou explained. “There are competing ideas for what causes droop, but there are common things you can do that address all of them.”

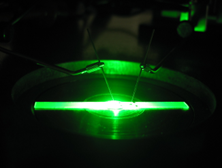

All LEDs, said Ryou, have a reservoir of negatively charged electrons and a separate reservoir of what are known as holes – essentially empty spaces in a material where an electron should be. Electrons and holes travel from their reservoirs and meet at a section of the LED known as an active layer, where they combine to produce light.

At high currents, though, electrons move from the reservoir to the active layer too quickly and are lost. Holes, meanwhile, move too slowly from their reservoir to the active layer. Exactly why this occurs at high currents but not low is a subject for debate.

Ryou stresses, however, that both problems can be addressed by altering the materials that separate the reservoirs from the active layer. These changes can limit the loss of electrons by regulating their movement and also encourage the easier migration of holes. The result would be highly energy efficient LEDs that put out high levels of light.

“The issues with commercially available LEDs are price and the efficiency,” said Ryou. “If we can create commercial LEDs that are at or near the technology’s theoretical efficiency, the devices would be smaller, cheaper to buy and cheaper to use. That would make them clearly superior to CFLs.”