If you don’t like the weather, give it a few minutes and it’ll change.

That bit of homespun wisdom is actually a big problem for the renewable energy industry. The amount of electricity produced by wind and solar power rises and falls with the amount of wind and sunshine. As a result, sometimes these technologies generate more energy than needed, sometimes they produce less.

Energy storage devices, which can save unused electricity for when it’s needed, are the obvious solution, but existing technologies just aren’t up to par. Batteries, for example, store electrical energy by converting it to chemical energy and then reverse the process when power is needed. A lot of energy is lost in these conversions, though. Other technologies have limited storage capacity or can’t distribute the energy they store quickly enough.

One possible solution: superconducting magnetic energy storage (SMES) devices like the ones being researched at the University of Houston Cullen College of Engineering.

Venkat “Selva” Selvamanickam, M.D. Anderson Chair Professor of Mechanical Engineering at the college, is collaborating on a grant awarded to Florida-based Tai-Yang Research Company (TYRC) to develop a SMES technology that stores energy with 95% “round trip” efficiency and can quickly discharge the energy it holds. The Advanced Research Projects Agency-Energy, the Department of Energy group that supports the development of game-changing technologies, is funding their work with a $2.15 million grant.

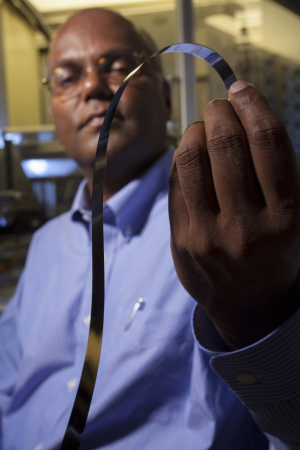

There are two essential elements to any SMES device: The first is a ribbon of superconducting material that transports electricity. Unlike standard copper wire, superconductors don’t lose any power in the form of heat. The second is the design of the coil that the superconducting ribbon is formed into. As electricity travels through the superconductor, the coil shape converts the electricity into magnetic energy.

While generating a magnetic field is the goal, it also presents a problem. “The magnetic field flux line [essentially the pull of magnetism] that the coil generates can move through and within the superconducting wire,” said Selva. “That can hurt the wire’s ability to carry electricity and lower overall device performance.”

The research team is addressing the problem in two ways. Selva, widely recognized as one of the country’s top researchers in the field of superconductivity, is working to improve the performance of the superconducting ribbon itself. By introducing small defects into the material, the flux lines can be held in place, allowing electricity to move through the superconductor unfettered. While he has conducted similar work for other efforts, notably a $4 million wind turbine research project also funded by ARPA-E, in those cases he deals with flux lines with lower magnetic field strengths than present in SMES devices. Trying to control the flux lines at these higher magnetic field strengths introduces a different set of challenges, he noted.

TYRC, meanwhile, is designing a coil that generates a magnetic field that introduces lower mechanical strain on the superconducting ribbon than traditional SMES systems, limiting the field’s impact on ribbon performance. This coil design will also use the superconducting ribbon being developed by Selva more efficiently. Since the superconducting ribbon is the most expensive part of the SMES device, the enhanced performance developed at UH and its more efficient use resulting from TYRC’s coil design will help to dramatically lower cost and improve SMES performance.

Combined, said Selva, these advances should improve the storage capacity of existing SMES devices by two to ten fold vs. standard SMES systems. The technology should also be scalable enough that it could be used for even small solar panel installations or a lone wind turbine.

“As wind and solar become more important sources of electricity, we’ll need to overcome their variability and use all the power they generate,” Selva said. “SMES devices are a very promising solution to both issues. TYRC’s lower strain and more efficient design is a new one, and it could end up producing the most effective and efficient SMES devices.”