A team of four engineering students represented the University of Houston at the 2013 IEEE Region 5 Robotics Competition in Denver on April 9, winning third place out of 26 teams.

Jacob Green, Timothy Hoang, Daniel Resendez, and Jeffrey Allen logged many hours, including weekends, in building and preparing their robot to meet the course specifications set forth by the competition.

"This was the hardest contest of all those I have seen in the 14 years I have been participating," said John Glover, professor of electrical and computer engineering and the team’s advisor. "Only 4 of the 26 teams even scored any points at all. I am quite proud of the team."

The course scenario simulated a forested area that had been ravaged by fire. Two-inch dowel rods represented downed trees, paint cans represented boulders, and wood posts were living trees. The purpose of the robot was to enter the "forest" and collect soil samples (3-inch-diameter plastic disks) to determine whether human intervention was needed to assist in re-vegetation.

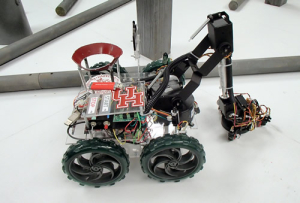

The team designed an autonomous robot tasked with navigating the 8'x 8' course of 16 sectors within a five-minute time limit, climbing over the obstacles and retrieving the six disks in a vertical motion. The locations of the disks were provided on a flash drive at the beginning of each round.

While other teams’ robots used magnets, the UH team employed a four-degrees-of-freedom robotic arm using a modified three-finger universal oil filter wrench to collect the samples.

The robot was sophisticated in its simplicity, performing well in spite of last-minute changes to the course specifications. Five infrared distance sensors gave environmental feedback, and the motors were monitored with wheel encoders and current sensors. Six light-to-voltage sensors were used with four LEDs to sense the difference in light intensity between the floor and disks.

At the competition, the UH team drew the attention of their competitors during the practice run, in which the robot retrieved all of the disks in under 4.5 minutes. Watch video of the practice run.

Green began working on the design of the robot early in the fall semester. He was in Professor Glover’s embedded systems class, and was encouraged to prepare the robot for the IEEE competition.

LyondellBasell agreed to sponsor the project after Green submitted a proposal to the company last semester. He will be working in instrumentation at LyondellBasell’s Pasadena refinery upon graduating this spring.

The robotics project, and others conducted by students in the UH department of Electrical and Computer Engineering, will be on display at the upcoming Graduate Research and Capstone Design Conference on April 26 at the UH Hilton.