Students at the University of Houston Cullen College of Engineering leave their mark in many ways throughout their academic career. They make the dean’s list, participate in undergraduate research and tutor those in need.

But for many, one of the most significant impressions made on both their instructors and themselves happens in one of the last classes required before completing the course work necessary to earn their degrees—senior capstone design.

The course gives engineering students a chance to apply their engineering education to a project that has real-world benefit, said Adam Capitano, the college’s biomedical advisor who has taught three of the last biomedical-related capstone classes.

“Engineering and class work has a real danger of evolving into esoteric problems that no one has the answer to,” said Capitano, “this makes it real.”

Whether it was just a fun challenge or an assignment designed to impact industry, projects completed during the spring semester ran the gamut.

Device Designed to Deliver Students From Distraction

Imagine a device that could aid teachers in delivering students with Attention Deficit Hyperactivity Disorder (ADHD) from distraction with the simple press of a button.

Well, a wireless system created by a group of biomedical engineering seniors may be able to do just this—assisting thousands of children suffering from ADHD who struggle to concentrate.

“The wireless device is designed to help young students diagnosed with ADHD to focus in a learning environment,” said Austin Head of the device he created with teammates Hung Lam, Eric Reyes and Meaghen Krebsbach. “The device does this by amplifying the teacher’s voice with a lapel microphone and wirelessly transmitting it to a discreet set of ear buds worn by the student. To help keep the student focused and on task, it also incorporated a remote that, when pressed, activates a tone that’s played in the ear buds—redirecting the student to the teacher’s voice.”

Created at the request of Dr. James Poysky, a Katy pediatric neuropsychologist, it’s a device that could one day be mass-produced to aid children with ADHD if a series of private trials being conducted by Poysky go well.

Constructed over the course of the spring semester, the system consists of both a teacher and student unit. These started out as a wireless transceiver and receiver kit. The group modified the wireless transmitter to create the larger, teacher unit tasked with continually transmitting the teacher’s voice to the student.

“We constructed an additional circuit that goes before the transmitter that handles changing the audio from the microphone to the tone directed to the student and stores the time of those tones,” Head said, noting when the button on the device is pressed, its homemade microcontroller (MCU) switches the transmission to a redirection tone of 500HZ in the student’s receiver unit for half a second. “Studies have shown that the brain automatically processes auditory information, even without conscious attention. This verifies that a tone sent to the child’s earpiece would be an effective way to redirect their attention.”

Poysky plans to test this first in a lab setting, using one of the key features designed into the device’s microcontroller to help provide the proof necessary to take his idea one step further—testing it in a classroom setting.

This particular feature could make it possible to track progress made over long and short time periods.

“The teacher’s unit stores the time the button was pressed, so at the end of the day you can transfer that data to a computer and maybe track progress over weeks or months,” Head said. “It can be used as sort of a diagnostic or research tool helping to determine whether it better keeps ADHD sufferers on task.”

Features such as this have made Poysky hopeful for the success of the device.

“This team of students did an excellent job in taking our idea and translating it into a reality,” Poysky, who has hopes of patenting the device, said. “I think that what impressed me the most is that they were focused on meeting our requirements, but they also thought ahead and anticipated potential problems or user-related issues and addressed them beforehand.”

Group Engineers Laser Guitar

Move over Guitar Hero; here comes Phantom-Stringed Madness.

Equipped with a touchpad fret board and lasers for strings, this guitar is one-of-a-kind. It took four UH electrical engineering students a semester and $1,063 to construct—converting a Fender Stratocaster to accommodate its on-board microcontroller unit (MCU) and laser interruption system.

Christopher DeLeon, David Nguyen, Christopher Kopp and Claudia Castrejon—none of whom play the guitar themselves—built the instrument. They consulted with guitar enthusiasts to ensure Phantom-Stringed Madness mimicked guitars already on the market.

Much of it does. Six lasers replace the strings on a normal guitar.

“This strum system uses six lasers and six photo sensors,” said DeLeon of the lasers that shine into assigned sensors making up the strum system. “When you break the beam of the laser the photo sensor changes the signal provided to the MCU and lets the MCU know you are playing that string.”

At the same time, when a key is touched on the fret board—actually a touch pad with 16 frets each represented by finger sensitive keys—another signal is sent to the MCU. It then takes the two inputs and matches them to one of 41 note tables.

“Through knowledge of basic physics, we developed a string vibration equation, which incorporated 12 different harmonics,” said Kopp. “We tested and refined the equation in MATLAB by comparing it to that of an acoustic guitar.”

But the group still had to create the sound.

“In order to create an audible sound from our guitar, we needed to assemble our sample signals into an analog output signal,” Kopp said, noting in order to synthesize the analog signal, they used the MCU to send digital samples to a digital to analog converter. “We knew it was necessary to remove sampling noise by passing the converted analog wave through a proper low-pass filter. The audio signal could then be sent over high-impedance amplified speakers for listening purposes.”

What the team had was a sound that fell somewhere in between an acoustic and electric guitar.

“We couldn’t have done this without our knowledge of engineering we learned at UH,” Kopp said. “We took what we learned here and expanded it and applied it to new and different things.”

The group, he said, is considering pursing a patent for the guitar.

Cell Printer Could Help Scientists More Cheaply Mimic Conditions in Body

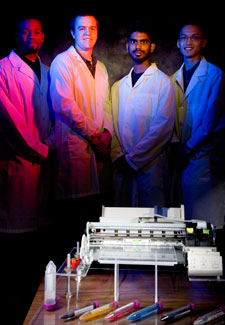

The ink Corey Hryc, James Liu, Valor Thomas and Shaun Khan have been working with over the course of the last semester is far from ordinary.

It’s living—literally.

This “bioink” is actually a solution of living Rat2 fibroblast cells. It is just one component of a system this group of biomedical engineering students created to pattern cells to more closely mimic conditions and alignment within the body.

“Modern tissue engineering seeks to reduce the demand of donated organs by growing viable replacement organs within a lab setting, but one of the biggest challenges facing these tissue engineers is that traditional tissue culture methods such as the Petri dish only allow for a monolayer of one type of cells,” said Thomas. “In the body, patterning is more complex than that.”

Adapted from a standard inkjet printer, the group’s device works to change this by offering the ability to systematically place cell types in specific locations that imitate what happens in the body. The students used two Epson Stylus Color 440 printers to test their idea, before finally constructing their final product with a third.

In order to achieve their goal, the printer was modified to accept 1.5mL eppendorf tubes containing the cellular solution, which were dispensed from the print head onto biopaper.

“The majority of the structures used to feed the paper restricted access to the print head, so they were removed,” said Khan. “It was crucial there was full access to the print head so the cellular solution could be dispensed on the biopaper.”

In the end, their device was capable of printing these fibroblast cells in a straight line at a resolution of about 130 microns at the tune of about $20.

It’s a fact that impressed their advisor Adam Capitano.

“There are not technologies that really maintain that order within the body,” he said. “The students have done a good job of making that order and composition. Cells are about 20 microns. They have placed within four or five cells.”

Khan still intends to build upon the device’s capabilities during graduate studies at the college, but, for now, the students are satisfied with what they were able to accomplish.

“This project proves that it is possible to control the placement of cells,” said Liu. “Controlling cellular placement allows the field of tissue engineering to become feasible because the cellular composition within the organs can be reproduced. Furthermore, the printing of various bioinks will allow researchers to mimic the diverse cellular compositions found within human organs.”