Researchers with the University of Houston’s Well Logging Laboratory presented a new technology at the group’s fall Industrial Consortium meeting that could result in consumers paying lower prices at the gas pump.

The Well Logging Consortium, hosted by the university’s Cullen College of Engineering, focuses on an essential aspect of oil exploration: recording key attributes of oil wells during drilling, from the density of the rock being drilled through to the size of oil deposits encountered.

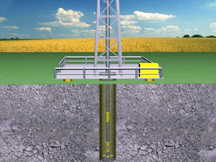

One of the practice’s biggest obstacles is transmitting data from the bottom of a well during drilling to the surface where it can be analyzed and drilling decisions can be made. Well logging researchers developed a new technology that should improve the transmission of data, resulting in faster and more efficient drilling.

Neither sending data through wires nor via standard wireless communication is possible due to the extreme conditions encountered in oil wells. At thousands of meters deep, temperatures in wells routinely surpass 150 degrees Celsius and pressure exceeds 20,000 pounds per square inch, said Richard Liu, director of the Well Logging Laboratory and UH professor of electrical and computer engineering.

Instead, a small pump near the bit of the drill repeatedly expands and contracts. This movement causes vibrations in the mud at the top of the well, which are translated into data at the rate of about 10 bits per second.

That rate, said Liu, is simply not fast enough to relay all the pertinent information to the people making drilling decisions. “The information is there. You can measure it, digitize it, store it, but you cannot send it to the surface.”

At its October meeting, however, UH well logging researchers presented a new system utilizing micro-electrical-mechanical-system, or MEMS-based technology that could increase the data transfer rate to as much as one kilobit per second.

MEMS technology enables the creation of near-microscopic machines on silicon wafers, the material used to construct computer chips. Well logging researchers used this technique to develop a series of MEMS-based radios, each no larger than a grain of sand.

As an oil well is drilled, a radios are distributed every six feet into the mud that fills the well, with the radio at the bottom of the well receiving data from the logging equipment. That information is then transferred up the well from radio to radio until it reaches the people on the surface.

The benefits of providing more information to the individuals making drilling decisions are clear, said Liu. “It will allow for faster and more accurate drilling. When you get more information from downhole, you have a better understanding of the well’s formation. The drilling becomes more efficient.”

And more efficient drilling could result in lower gas prices for everyone.

“It could have a great impact on oil prices,” he said. “Oil prices include everything, and drilling and exploration are pretty big portions of the cost. If this technology is viable, then costs get tremendously reduced.”

This advancement was only one of the nine presentations made during the Well Logging Consortium’s fall meeting. “The purpose of the consortium is to establish a scientific view of the well logging industry. We’re providing an independent, non-biased evaluation of the technologies developed in the industry,” said Liu.

In addition, the Well Logging Lab is home to the world’s only American Petroleum Institute-endorsed calibration facility for well logging tools based on nuclear technology.

While other institutions host similar groups, UH’s Well Logging Consortium is one of the oldest and most well-established, with the largest companies in the petroleum industry holding membership, including ExxonMobil, Shell, Chevron, Saudi Aramco, ConocoPhillips, BP, Statoil, BakerHughes, Precision Energy Services, Schulmberger and Halliburton.