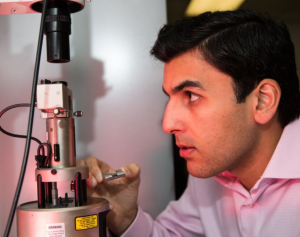

UH engineer Hadi Ghasemi, Bill D. Cook Assistant Professor of mechanical engineering, is set to change history with his invention of a new material that provides efficient heat dissipation at high temperatures and eliminates a 250-year-old scientific event known as the Leidenfrost Phenomenon.

If you've ever cooked a meal on your stove, you're probably familiar with the phenomenon, though you may not realize it. It occurs when you sprinkle a few drops of water into a hot skillet to make sure it's heated to your satisfaction. In those precious moments when the little droplets dance around – rather than boil – you are witnessing the Leidenfrost Phenomenon, in which a vapor barrier is created when liquid touches a hot surface, and that barrier prevents the drops from boiling on impact.

Scientist Johann Leidenfrost recognized the dynamic in 1756. Since then, scientists have been trying to prevent it, because its impact extends far beyond the kitchen. Think re-entry of a spacecraft or the Fukushima Daiichi nuclear disaster during which inadequate cooling led to three nuclear meltdowns.

“When you have a hot surface and you’re going to cool it down with a liquid, you need contact of the liquid with the surface,” said Ghasemi. “Otherwise the vapor becomes an insulating layer and it blocks the heat transfer.”

Now, a scientist -- among the hundreds around the world working to eliminate the vapor barrier -- has succeeded, effectively working around the problem. That scientist is Ghasemi.

The heat is on

“We have developed a new approach to completely eliminate this phenomenon,” said Ghasemi. His approach is the invention of a new metal surface called a “decoupled hierarchical structure” that removes the vapor barrier. His work has been published in the American Chemical Society's journal Langmuir.

The new structure is made of two layers: a micro-pillar surface with a nano membrane on top. The nano membrane keeps the droplet in contact with the surface while the micro-pillars take away the generated vapor. The new material allows unprecedented heat dissipation because there is direct contact with the liquid to the surface.

Ghasemi created the new surface in his Nano Therm lab and currently has a patent pending on the product. Lab members Nazanin Farokhnia, Seyed Mohammad Sajadi and Peyman Irajizad contributed to the research project. Ghasemi is already onto phase two of the material, to be made of copper in order to lower the cost.

Compared to today’s technology, no other surfaces come close to Ghasemi’s new one, which removes the bottleneck for the heat transfer process.

“With current surfaces, the maximum temperature reported is 400 degrees Celsius when the Leidenfrost effect occurs. But in our surface we couldn’t find any Leidenfrost, even at 600 degrees Celsius, and we believe we can go to much higher temperatures with no Leidenfrost effect,” said Ghasemi. “It is unprecedented heat dissipation.”

Infinity and beyond

Imagine one day that heat shields are made out of Ghasemi’s material, or power generators and chemical reactors. He does, as he researches the widespread applications of the material.

“We envision these surfaces opening a new avenue in thermal management through spray cooling,” he said.