It may not have been as sleek as other entries, but the Cougalac stole the show at the Chem-E Car Competition held at the American Institute of Chemical Engineers (AIChE) Southwest Regional Conference March 27.

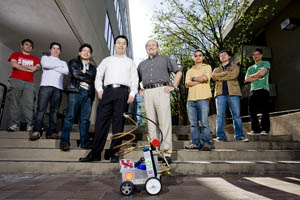

Named after its bulky, gas-guzzling relative—the Cadillac—the 26-pound car earned a team of eight chemical engineering students from the University of Houston a first place win and a ticket to the national competition in Salt Lake City, Utah this November.

“Lots of people were laughing, thinking it was too heavy,” said Richard Ma, the team’s captain. “It wasn’t. We wanted to try something new, something challenging. We did it.”

AIChE’s Chem-E Car Competition, which began in 1999, allows students to apply their engineering knowledge to build an alternatively fueled car. Though each team must follow a set of rules governing what their car can and cannot do, in the end the design of the vehicle is something all their own.

For the UH team—consisting of chemical engineering majors Ma, Vinh Nguygen, Tola Ouk, Kennan Stuhr, Allen Lo, Abel Morales, Jorge Cubas and Walter Barta—it was the result of an entire semester’s worth of brainstorming and a little trial and error.

With the help of Shell, the students were able to purchase supplies to build their car—designed to work on a pressure system. It relies on the decomposition of hydrogen peroxide using a catalyst (ferric chloride) that builds pressure in two tanks of the car. This pressure feeds oxygen to a pneumatic drill, which—much like a normal car—helps turn a gear that spins the front axle and moves the wheels of the Cougalac.

At the Beaumont conference, paid for, in part, by BP America and Chevron, seven schools were registered to compete. UH and three others were the only ones to make it beyond the first portion of the two-part competition—the poster presentation and safety inspection. These cars, deemed safe by judges, went on to demonstrate their car’s ability to travel 50 feet carrying a water payload of 500 milliliters. Further challenging them to make precise calculations under stringent deadlines—these specifications were given to competitors only one hour prior to the exercise.

Once a team was called, they had two minutes to start the drill and go the required distance before coming to a complete stop as close to the finish line as possible. This, Cubas said, was the difficult part.

“Brakes were not allowed,” Cubas said. “The stopping mechanism had to be triggered by a chemical reaction.”

Each team received two chances at the task. Their best attempt at meeting the 50 foot distance requirement was their final score. Cougalac beat its competitors with both runs—first with 44 feet and later with 51.5.

“It’s exciting to see these engineering students, from all levels in their study, work together as a team,” said Micky Fleischer, an adjunct professor of chemical and biomolecular engineering who serves as the faculty advisor for the team. “Not only are they working on engineering concepts that have them applying what they are learning to something real, but they were able to take the top spot, too.”

But even fresh off their win, the group is already focused on improving their performance in nationals. In the months leading up to the competition, they will be working on making modifications to improve the overall reliability of the car for the November contest.