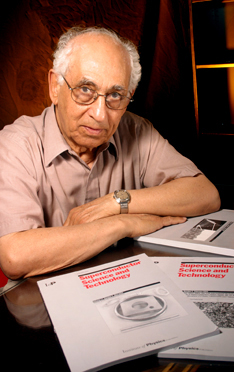

UH engineers became one of the first few in the world to fabricate wires and coils from magnesium diboride (MgB2), the most recent superconductor yet to be discovered, and their success may ultimately lead to better and less expensive electrical devices, lower energy consumption and lower consumer costs on electrical power. Their accomplishments were featured on the cover of the journal “Superconductor Science and Technology” in February and April 2004.

UH Mechanical Engineer Kamel Salama and his team at the Texas Center for Superconductivity and Advanced Materials (TcSAM) say the fabrication process is very promising because it may lead to less expensive and more efficient real-world applications such as power lines, magnetic resonance imaging devices, motors, generators and much more.

“The advantage of this superconductor is it’s much easier and cheaper to make into wires,” says Salama, who directs a team of nine researchers in the Superconductor Processing and Application Group at TcSAM. “We’re using the powder-in-tube method to produce wires and tapes that are jacketed by liquid hydrogen, which keeps the temperature at the necessarily low levels for this superconductor.”

The next step for this team of talented engineering experts will be to improve the wires by increasing their current carrying capability and improving the manufacturing process to increase efficiency and reduce cost. They are also working with a private company to scale up the process to the size needed for use in larger applications.

TcSAM provided the primary funding for this research.