Mechanical & Aerospace Engineering

The Department of Mechanical & Aerospace Engineering is proud of its partnerships that give students access to real-world problems faced in industry, while also helping companies and organizations find outside perspectives to tackle their problems.

Projects start in fall and spring and last 2 semesters (excluding summer). Project proposals are due mid-March (fall project start) and/or mid-October (spring project start). Submit your proposal here:

FALL PROJECT START INTAKE FORM

SPRING PROJECT START INTAKE FORM

Our Engineering seniors have a broad set of foundational skills in mechanics, fluid/thermal systems and material science. Our students are ready to apply their knowledge and skills to a wide range of physical problems, culminating in executed prototypes supported by measured validation data.

Student skills that would be a benefit to industry:

- Problem Analysis and Definition: Understanding stakeholder needs and developing engineering specifications in consideration of risks, timelines and budgets.

- Mechanical and Material Behavior: Application of material behaviors knowledge to analysis of structures under load and selection of components for mechanical designs.

- Fluid and Thermal Systems: Integration of mass and energy transfer theory for design of fluid flow, thermal, and power generation systems.

- System Dynamics and Control: Analysis of dynamic systems and manipulation of system response through electro-mechanical controls.

- Finite Element Analysis: Ability to apply theory and commercial simulation software to complex solid mechanics problems analyzing mechanical response and structural integrity.

- Experimental Validation: Verification of hypothesis and design specifications through physical measurements, such as temperature, strain, and forces, and through data analysis.

- Additional Skills:

- Traditional and rapid fabrication techniques

- Electro-mechanical systems implementation with microcontrollers

- 3D modeling and engineering drawing creation

Previous Project Examples:

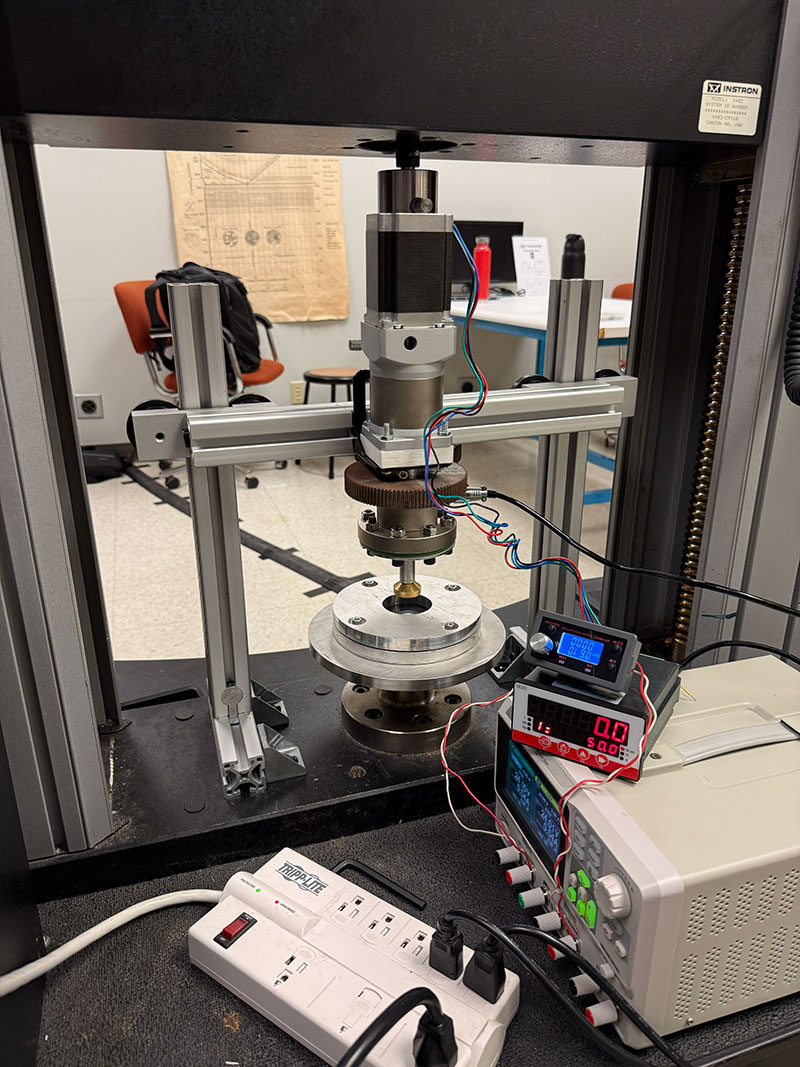

Coefficient of Friction Measurement Device Between Metals and Soft Polymers

Sponsored by SLB

Team Easy as Pi partnered with SLB to engineer a device that measures the coefficient of friction between soft polymers and metals under high pressure and temperature. Their innovative solution combines custom heating, compression and rotation into a single modular system—capable of running repeatable tests inside a universal testing machine.

Team Members: Jeryl Joseph, David Nguyen, Bryan Luna, Charles Ortiz

NASA DSD and Robotic Arm Adapting Mechanism

Sponsored by NASA

Team H.O.R.I.Z.O.N.S. designed, fabricated and tested a dynamic adapter that attaches to a device being developed by NASA’s Marshall Space Flight Center (MSFC). Delivered a dynamic connection between NASA’s experimental Domed-Shaped Device (DSD) and an UR-series robotic arm that will allow the DSD to dynamically tilt 30 degrees circumferentially to account for irregular terrain. H.O.R.I.Z.O.N.S. successfully demonstrated benchtop SMA control and actuation, as well as completed fabrication of both the 3D-Printed and Machined 6061 Al Prototypes.

Team Members: David Whaley, Cory Crow, Ashton West, Charity Golleher

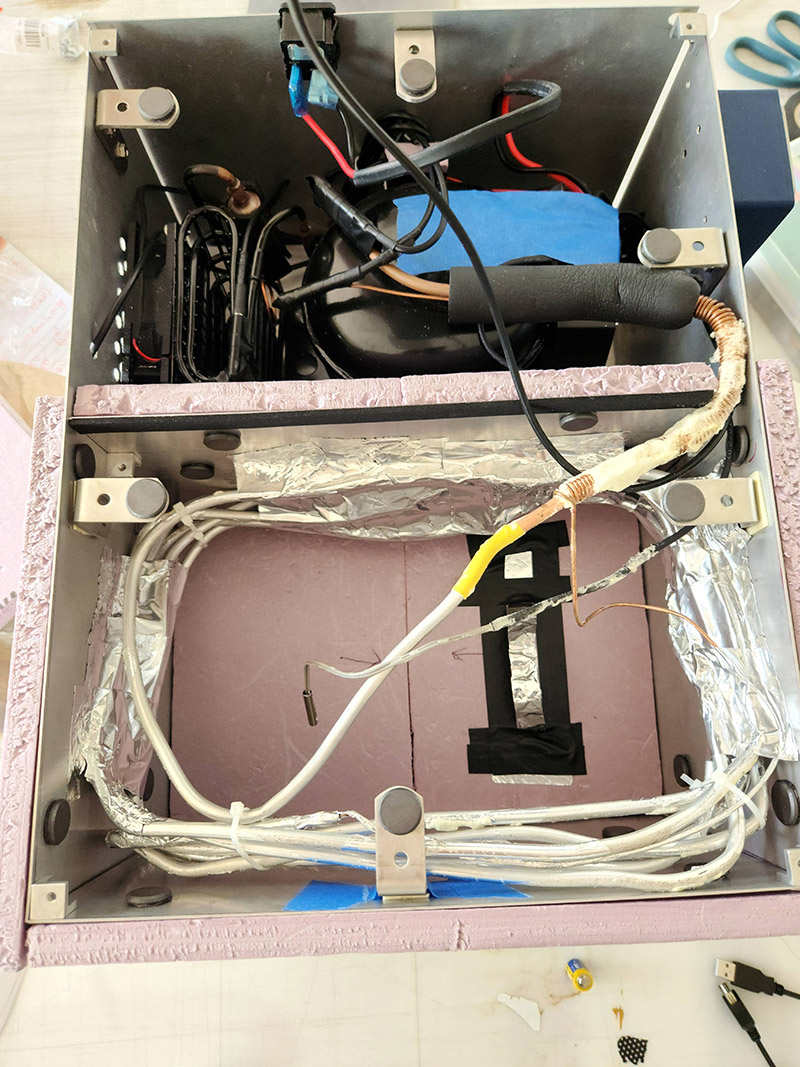

Heat Transfer Analysis System (HTAS)

Addressing a gap in the UH ME curriculum, "The Isobar" team developed a suitcase-sized Heat Transfer Analysis System (HTAS) to give students a hands-on way to explore thermal concepts like COP and heat transfer coefficients. The Arduino-powered device allows real-time experimentation with different insulation materials, bringing lab learning into the classroom.

Team Members: Brandon Nguyen, Nguyen Bui, Trung Nguyen, Nhan Tran