The University of Houston Chem-E-Car Team is well on its way to creating a tradition of supremacy in the Cullen College of Engineering. Fresh off their third place win at last November’s national Chem-E-Car competition, the team opened up the 2014 competition season with a bang, placing second at regionals in College Station. They will advance to the national competition this winter.

The Chem-E-Car competition is sponsored annually by the American Institute of Chemical Engineers. Teams must construct a car powered solely through chemical reactions that can haul a certain load several meters. However, the specific load and distance are not known until the competition day. At the regional competition, cars hauled 770 milliliters of water over a distance of 70 feet. The UH car’s motor is powered by a battery cell and stopped by an iodine clock reaction.

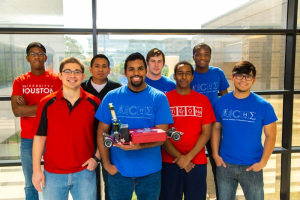

Paul Abraham, a chemical engineering senior, serves as Team Lead. Other team members include Jose Sachango, Addam Rufael, Eliazar Nava, Robert Dimaunahan, Abraham Aboiralor, Bruce Livingston and Hayden Trask. Several team members are underclassmen, and Abraham says that’s not necessarily an accident.

“The biggest benefit of having a younger team is the longevity of the program. When I bring in these younger guys, they know what we do, they know what we’re about, and they have an idea of how the contest works,” Abraham said. “It helps in the future, too, because they won’t be seniors for another two or three years, so I’ll have ensured that the program is going in the direction we’re working on.”

That direction is one of organization and high level performance. After serving as a team member last year and observing the competition process, Abraham initiated a plan this year to create a completely modular car. The car breaks into completely autonomous parts – a separate battery, calibration curve, solution setup, etc. – and team members are specialized in working on one specific element of the car. Not only does it streamline the process on competition day, but it enables team members to work on their assigned part without time constraints like other team members’ class or work schedules.

Now that the team has qualified for the national competition, they plan to weigh their options regarding modifications to the car. Last year’s car was powered by a pressure reaction, so the switch to a battery has resulted in a dramatic decrease in power. Abraham said in the months leading up to nationals, they’ll experiment with biofuels as a power source. They also plan to downsize the reactor size for the iodine clock to reduce the stopping time spread.

While the Chem-E-Car competition is a great way for Cullen College students to flex their engineering muscles, the process has real world applications. Abraham calls it the “plant analogy.”

“With a [chemical] plant, you’re doing the same thing as the Chem-E-Car. You’re running a chemical reaction; you have a start product and a desired end goal. On top of just making your product, you also have the additional goal of trying to make sure you do that the same every time. That’s what we’re doing here. We put in our battery, our chemicals, and our end product is our car stopping at a certain place. Additionally, we want to make sure the car stops at that place every single time when we do the reaction. If the car overshoots the target, I call it your plant blowing up. If the car doesn’t start, your plant didn’t run that day.”

With the national competition only a few short months away, the UH team is on high alert making sure their plant runs at full steam every day.