For all their virtues, electric vehicles have two major drawbacks: their cost – usually tens of thousands of dollars more than comparable gasoline-powered cars – and how far they can travel on a single charge.

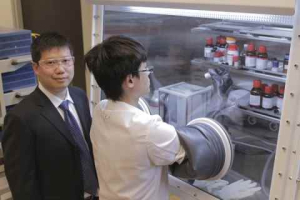

Yan Yao, assistant professor of electrical and computer engineering at the University of Houston Cullen College of Engineering and Robert A. Welch Professor with UH’s Texas Center for Superconductivity, will work to solve both of these problems thanks to a major grant from the Advanced Research Project Agency – Energy (ARPA-E).

Part of the U.S. Department of Energy, ARPA-E invests in high-potential, high-impact technologies that need further development to win private sector funding. This grant comes through its new RANGE program (Robust Affordable Next Generation EV-Storage), a $36 million initiative to radically improve energy storage systems for electric vehicles (EVs). Though the final amount of the award is still being negotiated, the application sought $760,000 for just one year of work.

Yao and his collaborator, Jeff Xu, a principal scientist with the Southwest Research Institute (SwRI), will use the funding to develop an entirely new type of battery for electric vehicles.

“Yao’s work is an example of the ways in which the university’s energy research is expanding beyond the traditional boundaries of hydrocarbons, wind and solar energy,” said Ramanan Krishnamoorti, Chief Energy Officer at UH and professor of chemical and biomolecular engineering. “Battery technology is a critical enabler for the monetization and commercialization of electrical vehicles and for the integration of intermittent sources such as wind and solar energy. New-generation safe batteries, and less expensive batteries, will be the key to making electric vehicles affordable and practical.”

According to Yao, this is because existing EV batteries not only determine how far these vehicles can travel, they also drive up their price. “It’s a linear relationship. The longer you want to drive the more expensive the vehicle. The battery is a big driver of cost.”

First, a quick primer on how these batteries work. All EV batteries generate electricity through a pair of chemical reactions. These reactions occur on different sides of the device, the anode and the cathode. Separating the two sides is an electrolyte, which allows molecules involved in the chemical reactions to travel back and forth between the sides.

The only existing batteries strong enough to power a full day’s worth of driving use electrolytes that are both expensive and extremely flammable. This is a major problem in EV design, said Yao.

“Because these batteries are so flammable and fragile you have to put a lot of protection around them. This protection is inactive. You cannot store energy with it. It’s basically dead weight that reduces the effective energy density and drives up the price of the vehicle.”

Yao’s solution: develop a lithium-ion battery that uses a water-based electrolyte. Dubbed aqueous lithium-ion batteries, they should be cheaper and safer than existing EV batteries. Even better, they won’t need to be surrounded by dead weight to shield them in an accident. That would leave more room for the battery itself, resulting in longer driving ranges per charge.

While aqueous lithium-ion batteries have been built in laboratories, their performance has not been good enough to draw industry investment. This is due to the chemicals on both sides of the aqueous batteries. Put simply, there are no materials that can generate a commercially acceptable amount of energy in a functioning aqueous environment.

Yao, though, has struck upon an entirely new class of material that can be used for these devices’ anode side, the most problematic part of an aqueous lithium-ion battery. Though he can’t reveal the exact compounds he’s experimenting with, he can say that they are organic compounds, meaning they contain at least one of the four organic elements: carbon, hydrogen, oxygen and nitrogen.

Few battery researchers, Yao said, have even considered using organic materials simply because their training focuses on inorganics. Yao himself is unusual in that he has worked extensively with both types of compounds.

One of the main advantages of organics in battery research, he said, is their design flexibility. It is easy to tune these compounds to meet different goals, such as redox potential, surface energy, or faster battery charging and discharging. Added Xu: "This joint research effort will leverage SwRI's expertise in battery chemistry, cell fabrication, and vehicle-level development to provide value to the overall project and to the area of EV safety."

The great potential of this new type of battery has set a high bar for Yao and his team. He will use the funding to bring on board multiple post-doctoral researchers and students. At the end of the one-year project the team is expected to produce not just a few academic papers but an actual working prototype battery that has been fully characterized for safety, energy density, charge and discharge rates and more.

“We’ve got a lot of work to do in one year,” said Yao. “In the end we want to have a prototype and a patented technology that someone can build a business around.”