Batteries capable of powering the electric vehicles of tomorrow may be available sooner than we think, thanks to more than $5.7 million in seed funding provided through the Department of Energy’s Battery500 consortium. Yan Yao, associate professor of electrical and computer engineering at the Cullen College, is among 15 principal investigators funded through the consortium, which is led by DOE’s Pacific Northwest National Laboratory and includes multiple partner universities and national labs.

The seedling projects were announced July 12 as part of a larger unveiling of a total of $19.4 million in new DOE funding for vehicle technologies research. The latest phase of funding focuses on high risk, high reward, proof-of-concept research that could potentially identify major energy storage solutions.

After 18 months, the most promising of the projects will be selected to move forward to phase two with additional funding.

Battery500’s goal is to develop lithium-metal batteries that can pack more than twice the amount of energy in the same size battery cell. Doubling the specific energy of batteries will allow electric vehicles (EVs) to drive farther distances on a single charge while reducing the cost and weight of the vehicles.

Yao’s project focuses on using organic materials to increase the amount of energy that solid-state lithium batteries can store and discharge.

Tomorrow’s batteries today

After releasing its latest EV battery in 2016, Tesla CEO Elon Musk admitted current lithium-ion battery design and chemistry prevent them from packing more power into the battery packs.

“This is quite close to the theoretical limit,” he said, likening the quest to stuff more power into the battery packs to “stuffing 11 pounds into a 10-pound bag.”

Musk’s lamentation underlies the importance of developing new battery technologies using different materials and chemistry, says Yao. The most powerful Tesla battery has an energy density of about 300 watt-hours per kilogram, with most standard EVs maxing out at about 170-200 watts per kilogram.

The Battery500 consortium, by comparison, aims to build a battery cell with a specific energy of 500 watt-hours per kilogram.

“If we want to go much further we need to consider different ways of storing energy,” says Yao. “We need to increase our fundamental understanding of existing battery technologies.”

One such existing technology is solid-state batteries, which show promise in beating out their lithium-ion counterparts in terms of both energy density and safety. Current lithium-ion batteries use a flammable liquid electrolyte to transport positive lithium ions between the cathode and anode. Solid-state batteries use solid electrolytes, potentially enabling the use of a lithium metal anode.

But solid-state batteries come with their own set of drawbacks. For starters, solids don’t conduct electricity as efficiently as liquids, which means the time it takes to charge the batteries might be longer while the battery life itself is much shorter than lithium-ion batteries.

Takeshi Uchiyamada, Toyota chairman and the engineer who led the development of the first Prius hybrid, is hoping to gain ground in the race to develop the next-generation of electric cars by trying to overcome some of the inherent drawbacks with solid-state batteries.

So far the automaker hasn’t succeeded in extending the life of the batteries. Uchiyamada noted that he doesn’t expect consumers will buy electric cars if they need to replace the battery packs every three years.

It isn’t just electric vehicle manufacturers who will benefit from today’s arrival of tomorrow’s batteries, Yao says. “We need this for alternative energy to take off – wind and solar, for example. We need to be able to store large amounts of energy off the grid. It’s a big challenge.”

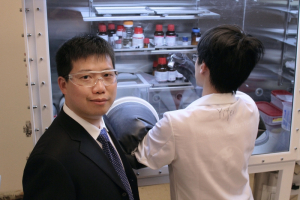

The energy of Yao

For Yao, the challenge of creating better, safer batteries energizes his research group. His team specializes in the creation of next-generation batteries that use earth-abundant, organic materials such as magnesium to increase energy density and overall safety.

A paper published in Nature Materials in June outlines Yao’s discovery of a new class of inexpensive organic materials called quinones, which give aqueous batteries a longer life, more chemical stability and the ability to function across a range of temperatures. The discovery could benefit a range of industries including renewable energy, transportation and personal electronics.

“We are looking at new organic battery chemistries that can rival the existing ones,” Yao says, adding that he hopes to explore the use of quinones for solid-state batteries, coupling the material with lithium metal. “Ideally we want to combine the safety of aqueous batteries with the high energy density of lithium-ion batteries.”

Using a mixture of computational analyses and experiments, Yao is charged with proving to the Battery500 consortium that greater energy density and battery life can be achieved by using new, organic materials for solid-state lithium-ion batteries. If proof-of-concept is achieved, Yao will focus on the manufacturability of his novel batteries.

“I’d like to partner with industry to see our new batteries make it to the consumer market,” Yao says. “Our ultimate goal is to not only improve battery technologies, but also to improve people’s lives.”