The Cullen College of Engineering (CCE) is housed in Engineering Buildings 1 and 2, the Science and Engineering Research Center (SERC), the Durga D. and Sushila Engineering Research Agrawal Building (AERB), Health and Biomedical Sciences 1 and 2, the South Park Annex, the University of Houston (UH) Technology Bridge, and the University of Houston Katy Campus. In addition to classrooms and state-of-the-art laboratory facilities, College faculty, students, and staff have access to numerous other supporting infrastructure, research, innovation, and teaching facilities.

Cullen College Facilities

Engineering Buildings 1 and 2

Engineering Buildings 1 and 2 house five of the College seven departments (Chemical and Biomolecular, Civil and Environmental, Mechanical, Electrical and Computer, and Industrial) and several of its undergraduate and graduate programs (PROMES, Subsea, Materials, Aerospace are examples). The two buildings also house the Engineering Computing Center (ECC) and the Engineering Educational Resource Center (EERC) in addition to the Career Center, the Undergraduate and Graduate administrative offices, the Office of the Dean, Research and Facilities, Engineering Programs in Innovation and Entrepreneurship (EPIE), and Research Computing (RC). The two buildings house several research laboratories, consortia and centers and institutes.

Science and Engineering Research Center (SERC)

The Science and Engineering Research Center (SERC) building is home to the materials research laboratory for Civil and Environmental Engineering, the Clean Room Core Facility, and the Biomedical Engineering (BME) Department. The building is also home to other life sciences and bioengineering research laboratories for CCE faculty.

Durga D. and Sushila Agrawal Engineering Research Building (AERB)

Completed in 2016, the newest engineering building on the main campus, the AERB is home to the Salah and Chang Turkemani Research Collaboration Room, the Hari and Anjali Agrawal Conference Room, the Cameron–a Schlumberger Company Laboratory, the Mehta Family Engineering Research Center, the Shell Oil Research Floor, and the Jennifer Luna Sing Conference Room. The AERB houses interdisciplinary research collaborative laboratories focused on catalysis and synthesis, materials, polymers, water treatment, sensors and optical technologies. The AERB also houses the Hewlett-Packard Enterprise Data Science Institute (HPE-DSI) University Center.

Health and Biomedical Sciences 1 and 2

CCE faculty has research laboratories in Health and Biomedical Sciences (HB 1 and HB 2) and access to the animal care facilities in HB 1.

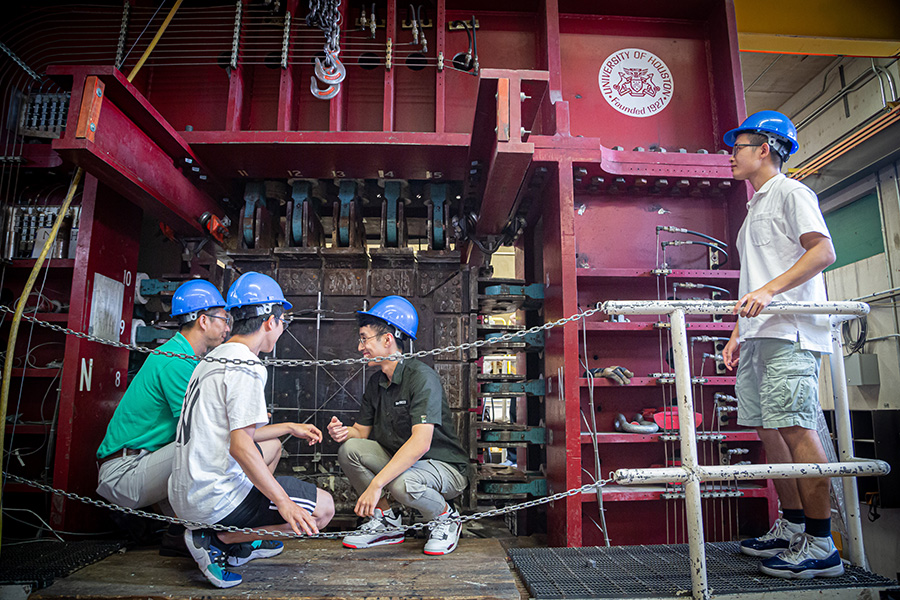

South Park Annex

The Structural Engineering Laboratory in the Civil and Environmental Engineering Department occupies the South Park Annex. The facility includes 30 ft. by 60 ft. and 20 ft. by 60 ft. strong floors and houses large-scale test equipment, including a biaxial fatigue testing machine, a 2.5 million pound MTS test system, and a universal panel tester. The universal panel tester can be used to perform biaxial and triaxial tests and is the only one of its kind in the United States and the most versatile of the three panel testers in the world. The laboratory also offers a fully equipped welding shop and concrete casting room, as well as student and faculty office space and a conference room.

Technology Bridge

The UH Technology Bridge is located in close proximity to the main campus and is home to the Petroleum Engineering Department and the Geosensing program in Civil and Environmental Engineering and its National Science Foundation funded National Center for Airborne Laser and Mapping (NCALM). The Technology Bridge also houses the ASMI (Advanced Superconductivity Manufacturing Institute), the Texas Center for Clean Engines Emissions and Fuels, and the College Machine Shop.

Katy Campus

This campus is located near the near the intersection of I-10 and the Grand Parkway. This 80,000-sq. ft-facility features state of the art laboratories and studios. For more information on Katy, contact Dr. J. R. Rao, Associate Dean for Engineering Programs at the University of Houston at Katy.

Shared Facilities

The research efforts underway at the CCE involve a unique blend of high-end instrumentation and faculty expertise. Several facilities within the Cullen College offer external testing and research capabilities to research groups, government agencies and other entities interested in advancing technology and discovery.

- Biomedical Core Research Facility

- The Clean Room

- GM-2D XRD

- Texas Center for Clean Engines Emissions and Fuels

- Nanofabrication Facility – An open access shared user facility housing state-of-the-art microfabrication equipment to build devices.

Faculty Research Facilities

Several faculties in the CCE operate state of the art experimental and computational facilities. Explore some of their facilities and state-of-the-art research equipment.

- Structures and Artificial Intelligence Lab – PI Dr. Vedhus Hoskere, Civil and Environmental Engineering

- Tissue Imaging Research Laboratory – PI Dr. David Mayerich, Electrical and Computer Engineering

- Polymer Synthesis Research Laboratory – PI Dr. Megan Robertson, Chemical and Biomolecular Engineering

- Nanotherm Research Laboratory – PI Dr. Hadi Ghasemi, Mechanical Engineering

- Biomedical Optics Research Laboratory – PI Dr. Kirill Larin, Biomedical Engineering

- Superconductivity Research Laboratories – PI Dr. Venkat Selvamanickam, Mechanical Engineering

- Battery Testing Research Laboratory – PI Dr. Haleh Ardebili, Mechanical Engineering

- Robotic Swarm Control Research Laboratories – PI Dr. Aaron Becker, Electrical and Computer Engineering

- Well Drilling and Completion Flow Loop Laboratory – PI Dr. George Wong, Petroleum Engineering

- Power Electronics Research Laboratories – PIs Dr. Kaushik Rajashekara, Dr. Harish Krishnamoorthy, and Dr. Xingpeng Li, Electrical and Computer Engineering

- Energy Materials Research Laboratory – PI Dr. Yan Yao, Electrical and Computer Engineering

- Advanced Imaging and Sensing Research Laboratory – PI Dr. Xiaonan Shan, Electrical and Computer Engineering

Research

Departmental Research

Contact Us

Mail: University of Houston

Cullen College of Engineering

Engineering Building 2, Room E421

4222 Martin Luther King Boulevard

Houston, TX 77204-4007

egrgrant [at] central.uh.edu (egrgrant[at]central[dot]uh[dot]edu)

Google Map

UH Map & Driving Directions

(includes parking information)